RAW MATERIAL STORAGE

- We have 4-Nos Storage Racks in our workshop with 4 divisions to store Pipes and Bright Rounds for Idler Roller Manufacturing. Each rack has a total load capacity of around 5 tons.

- The racks are installed under a crane with a capacity of 5 Tons for faster and smoother loading and unloading.

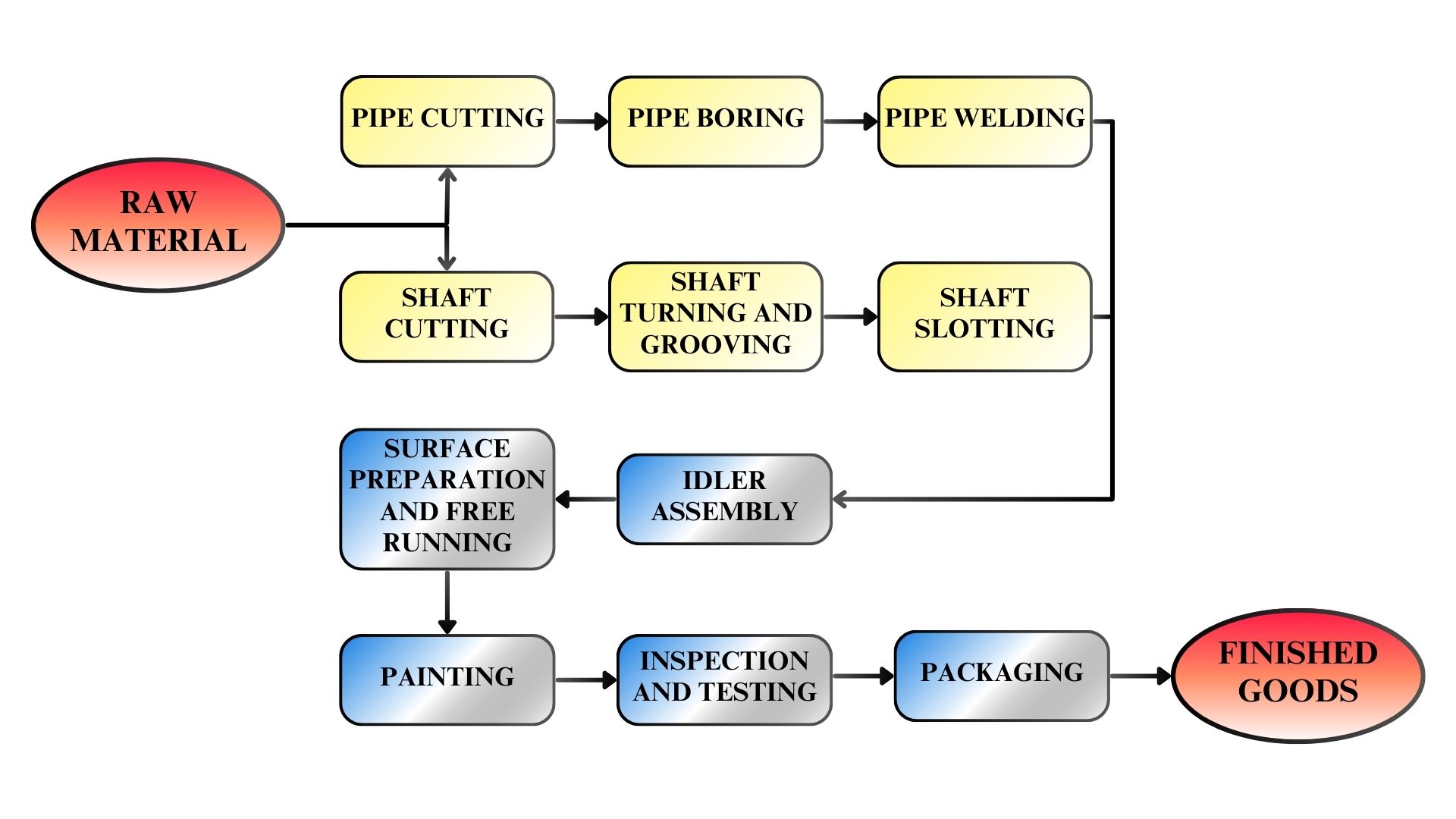

IDLER PIPE CUTTING

PLC controlled Rotary-Head Idler Pipe cutting machine is installed with a capacity to cut 750 Nos Idler Pipes in one shift.

IDLER PIPE BORING

With our SPM Double-Headed Boring Machine , we ensure that idler shell ends are simultaneously counter-bored to provide true concentricity. This machine is PLC Controlled and has a capacity to counterbore 500 Idler pipes per shift

IDLER PIPE WELDING

Our “ADOR” – make Simultaneous Both Sides Pipe Welding Machine ensure smooth weld finish and fast turn-around time , enabling us to follow strict delivery schedules of our clients . This machine has a capacity to weld 500 Idlers per shift.

IDLER SHAFT TURNING AND GROOVING

We have 3 Nos HMT Make Capstan Lathes for centre to centre turning of idler shafts.

With skilled and experienced operators, we ensure that the bearing fitting diameter of the idler shaft is maintained withing a strict tolerance of 0.02mm.

IDLER SHAFT SLOTTING

We have installed an SPM for simultaneous milling of idler slots with a capacity to slot over 800 Idler Shafts in one shift.

IDLER BEARING ASSEMBLY

Our Simultaneous-Hydraulic-Bearing Pressing machine ensure distortion free and accurate bearing assembly into the housing .This machine can assembly over 500 idlers in one shift.

SURFACE PREPARATION AND FREE RUNNING

We have installed and commissioned equipment for idler free running and surface preparation before painting. The Idlers are fixed onto the fixture plates given and abrasive sheets (emery) is used to clean the idler surfaces for proper painting

PAINTING

Our idler roller manufacturing facility features an advanced Paint Booth expressing the environmental consciousness of our company ensuring a high-quality durable finish for enhanced corrosion resistance and longevity.

INSPECTION AND TESTING

- We have set up a modern laboratory specially intended for thorough testing of conveyor idler rollers. We have installed the following testing machinery:

- Friction Factor testing machine

- Water Ingress Testing Machine

- Dust Penetration Testing Machine

- Axial Float and Resistance to Press-out Testing Machine

- Radial Run-out Testing equipment

PACKAGING

- We understand that idler rollers are procured in advance by our clients and may even be kept on shelves for a considerable time. We ensure that any idler rollers dispatched from our facility is plastic wrapped and heat sealed so that there is no scope of rusting or any other deterioration. These plastic wrappers are more than 120 microns thick and easily meet the government regulations.

- Besides wrappers, we comply to the packaging demanded by our customer during dispatch as per their specifications if any.

STORAGE

Om Engineering Works (I) Pvt. Ltd. is a regular supplier of idlers to more than 3000 stone crushing plants based in our locality.

Our customers demand that we keep idlers in stock so that they don’t have to. We have a shed of 2500 Sq. Feet for storage and stock keeping of our idlers. This dissolves clutter in the workshop and assists in faster turnaround time.

using WordPress and

using WordPress and