UHMWPE IDLER ROLLERS

UHMWPE (Ultra-High-Molecular-Weight Polyethylene) Idler Rollers

Modern businesses are rapidly shifting towards high-speed conveying.

Belt speeds in the range of 4 to 6 m/s have become typical. Designers are pushing for belt speeds up to 9 m/s.

UHMWPE rollers manufactured by OEWIPL Offer significant benefits in high speed conveying , application as compared to steel rollers .

ADVANTAGES OF UHMWPE IDLER ROLLERS OVER STEEL ROLLERS

Prevents Conveyor belt Damage

- When an idler roller seizes due to bearing failure , the belt wears down the roller shell. In case of steel idler rollers , the sharp edges of the bearing housings cut through the conveyor belt. Once belt is damaged , it causes expensive downtime.

Reduction in Vibration of Conveyor Structure

- In High speed conveyors, even minor radial run-outs of conveyor rollers cause a lot of Vibration in the structure . This is difficult to control in steel rollers.

- OEWIPL manufactures UHMWPE rollers with negligible run-out . This prevents ‘Jumping’ of the conveyor belt upon the rollers during operation and substantially reduces structural vibration.

Avoids damage due to Corrosion

- Surface corrosion of steel rollers exposes the conveyor belt to sharp edges and eventual . As UHMWPE is non-corrosive, the problem of belt damage due to rusting is not there.

Reduces Noise Pollution

- UHMWPE rollers have low-friction , lightweight construction, thus minimizing vibration and sound compared to traditional steel idlers.

MATERIAL OF CONSTRUCTION

IDLER PIPE

AS PER IS 9295

IDLER SHAFT

AS PER IS 532

BEARING HOUSING

AS PER IS

SEAL SETS

NYLON – 6 AS PER IS 13523

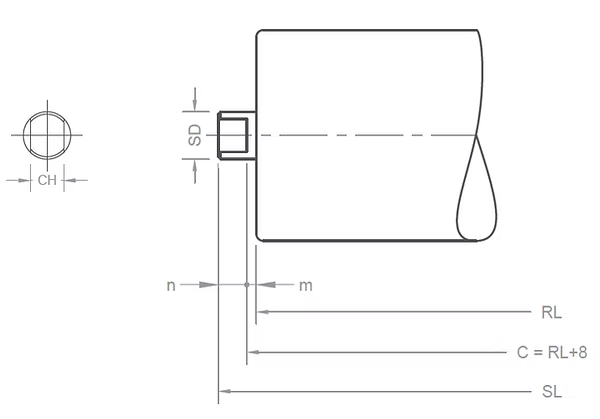

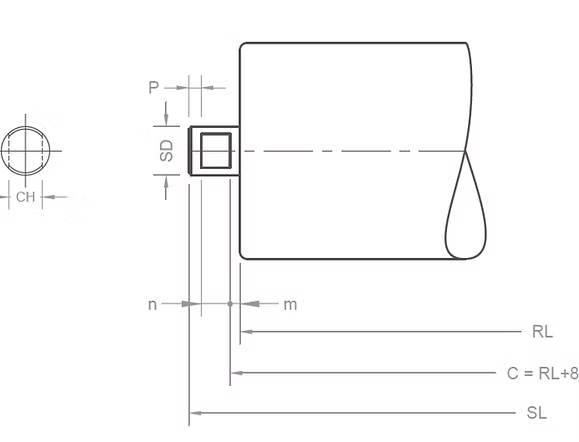

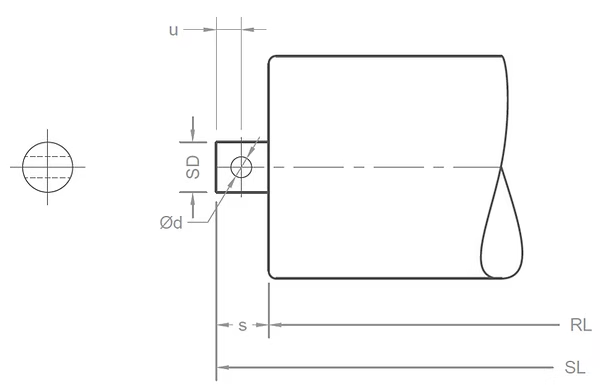

TYPES OF SHAFT END ARRANGEMENTS

PLAIN SHAFT END / OPEN SLOT SHAFT END

CLOSED SHAFT SLOT END

using WordPress and

using WordPress and