OUR PRODUCTS

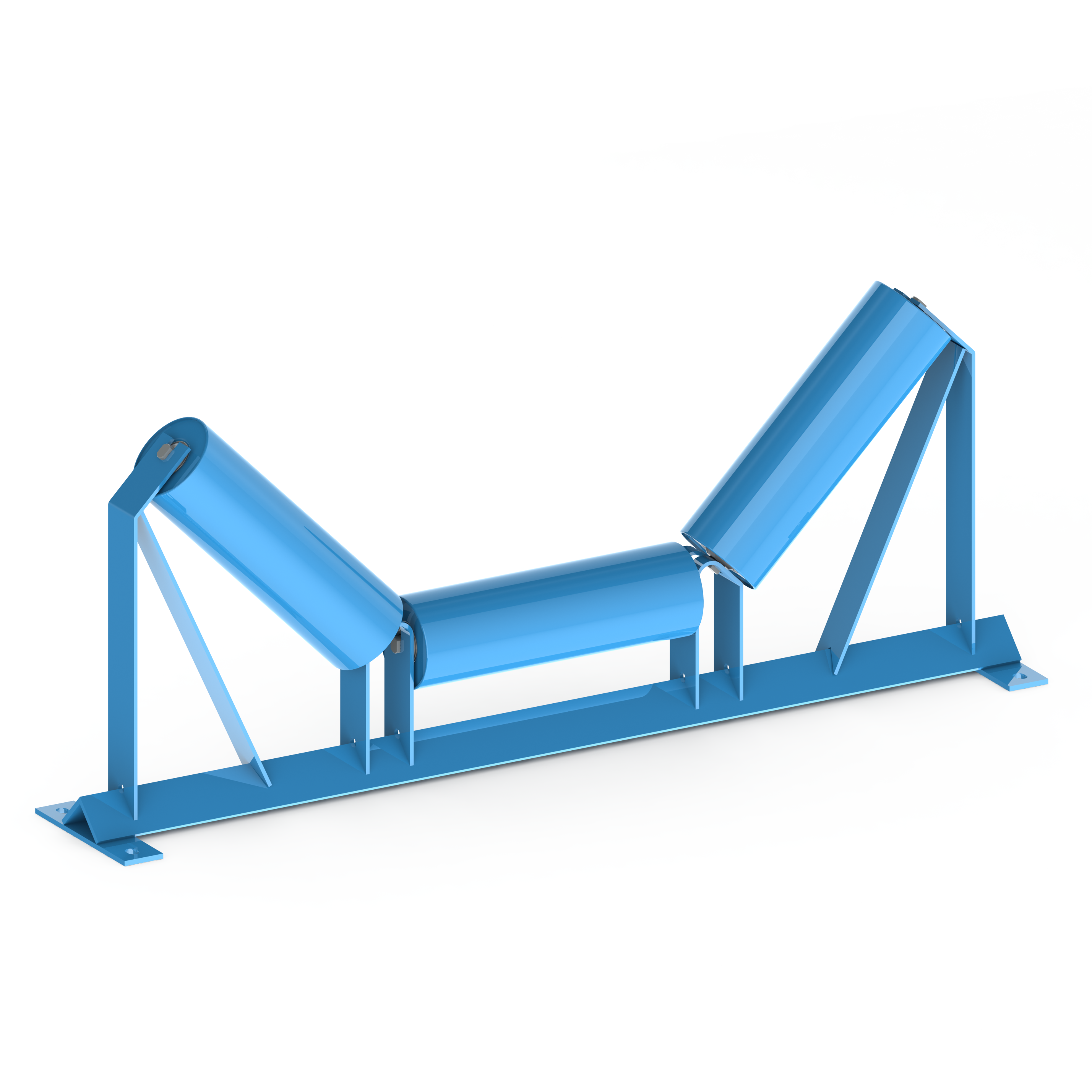

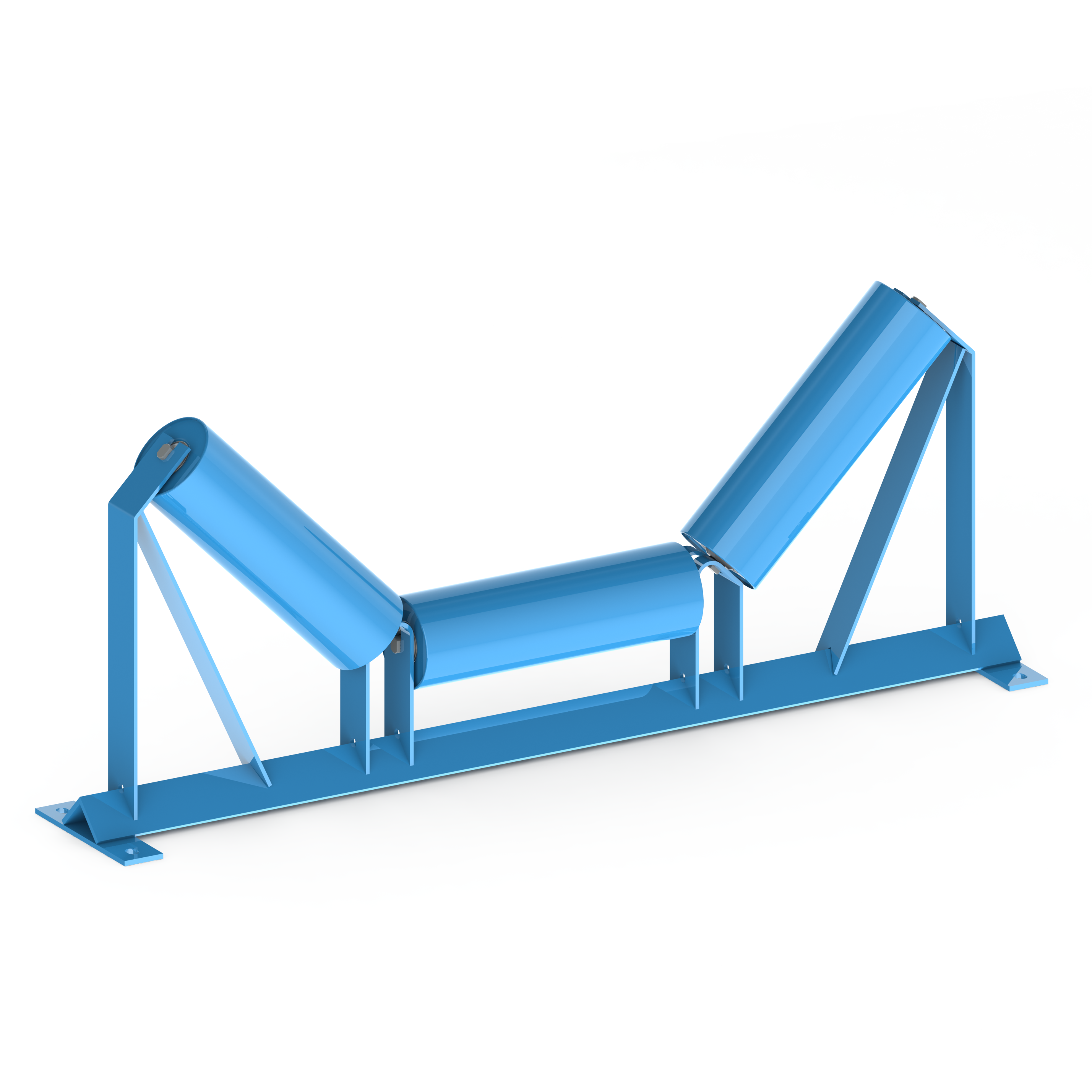

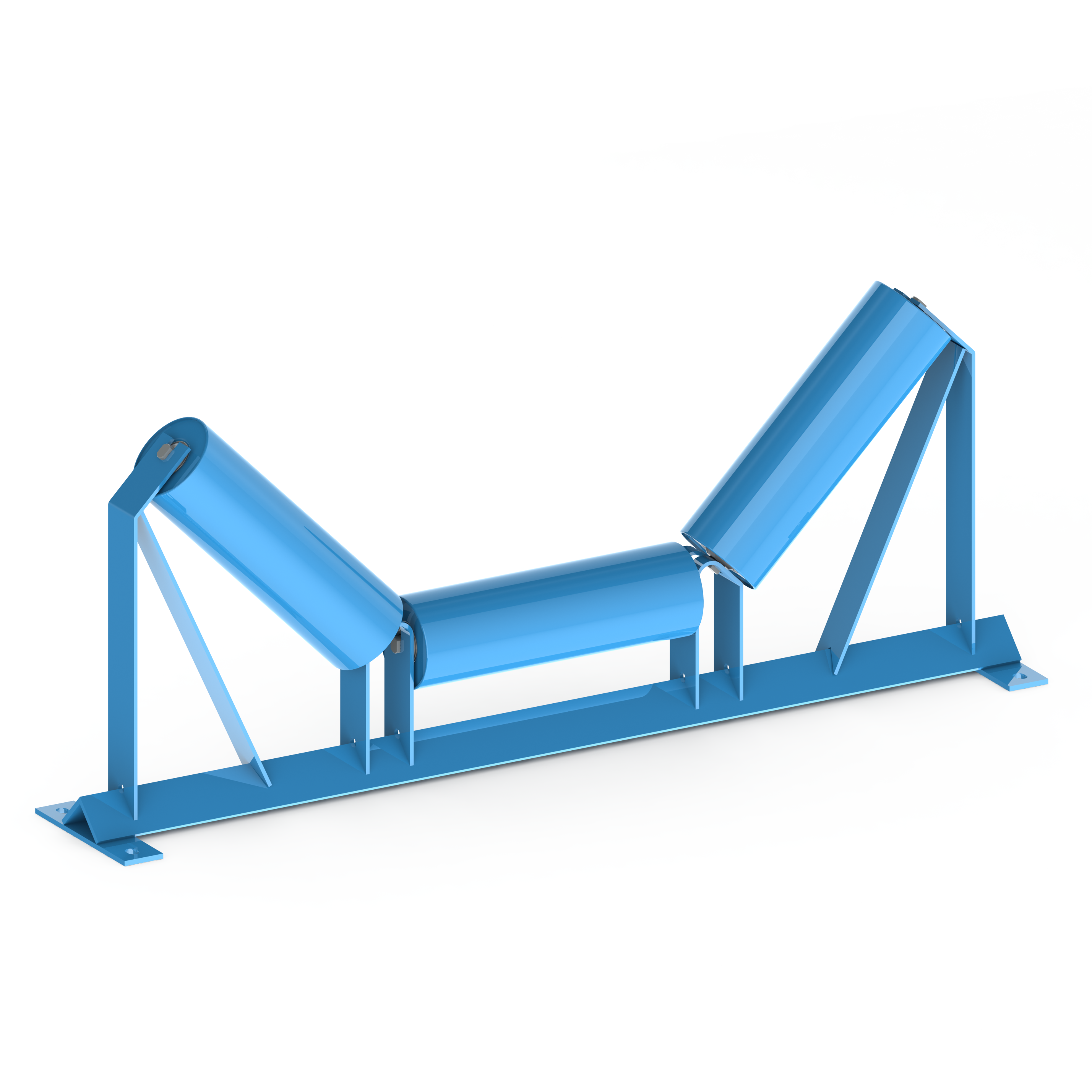

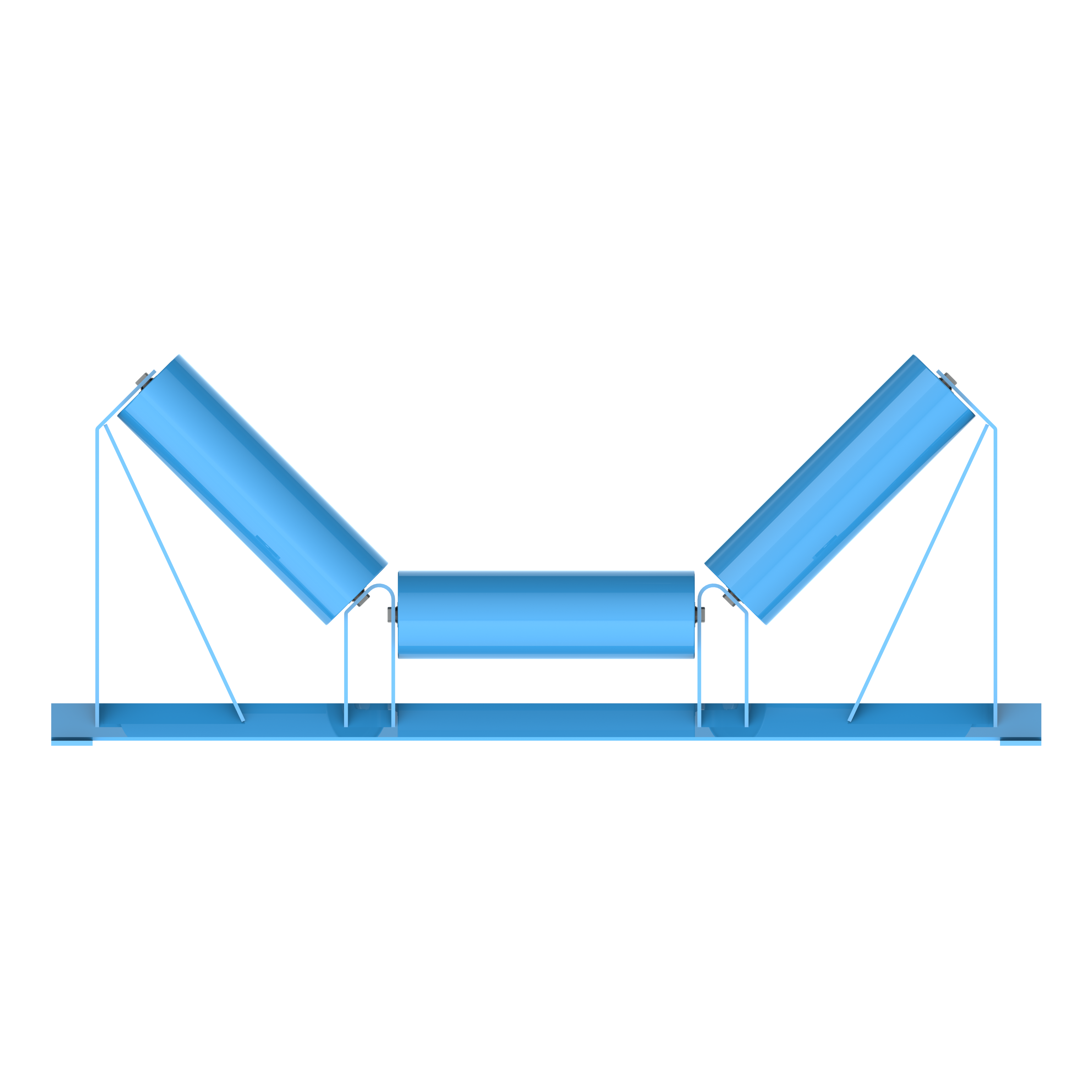

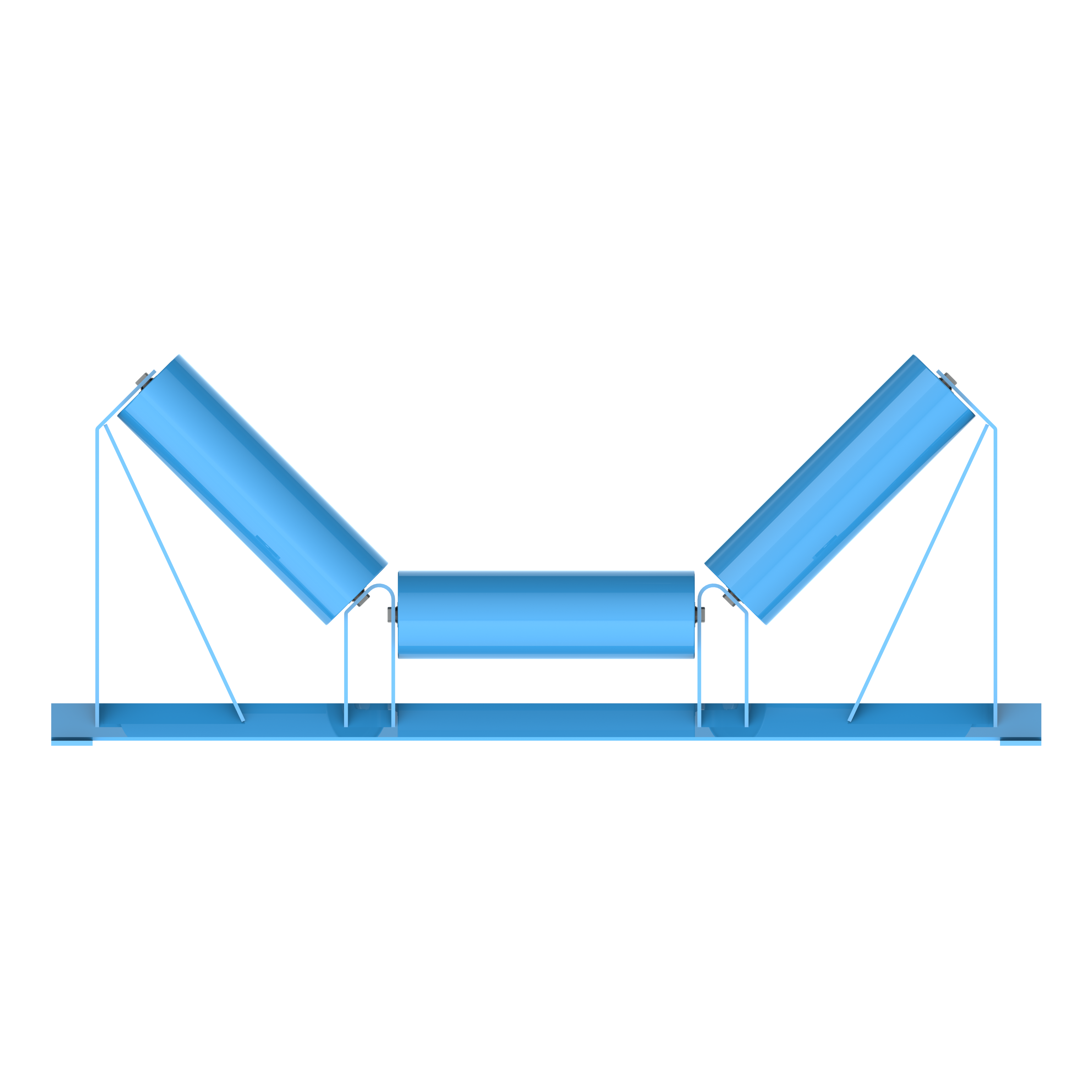

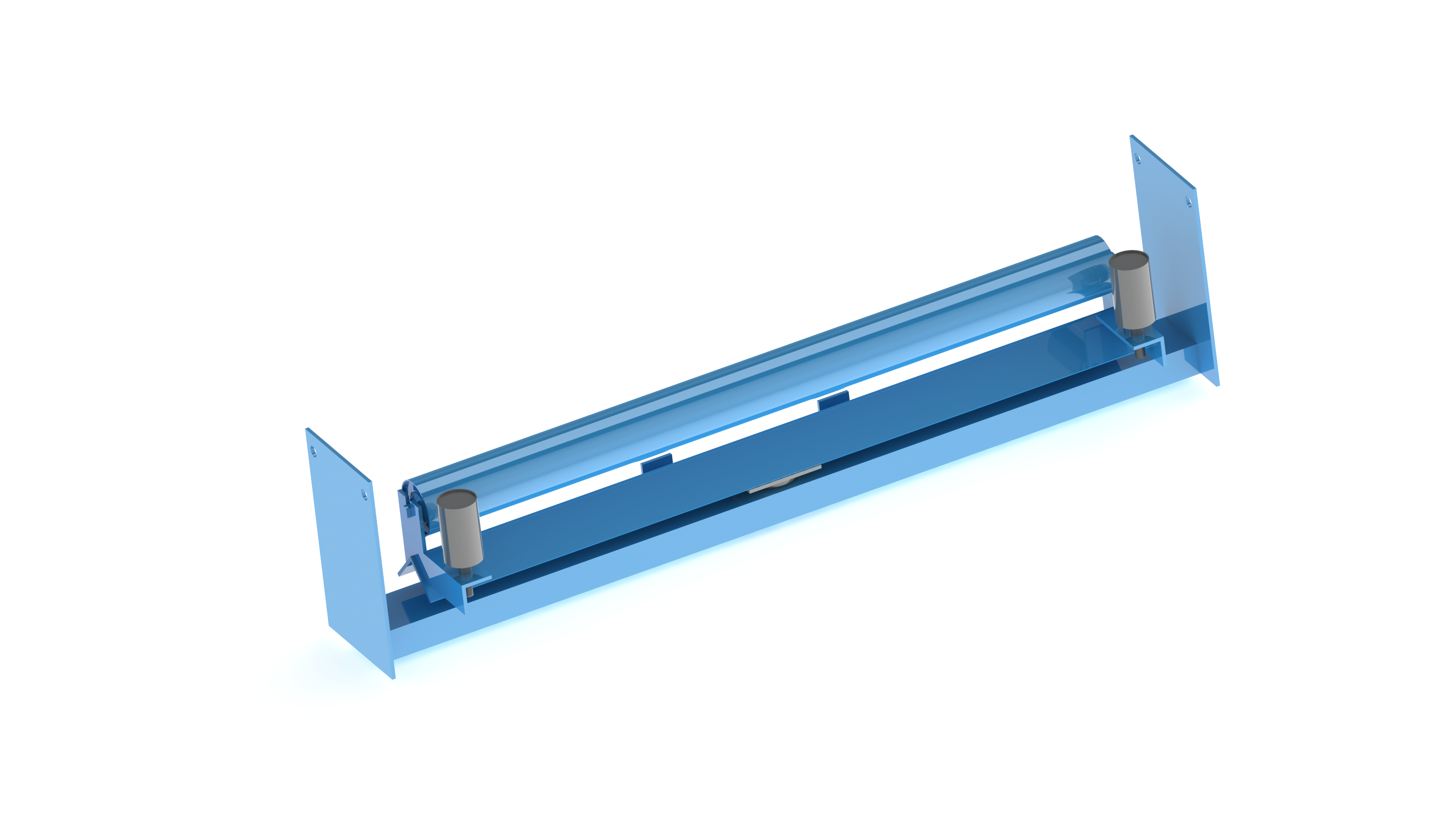

CARRYING IDLERS

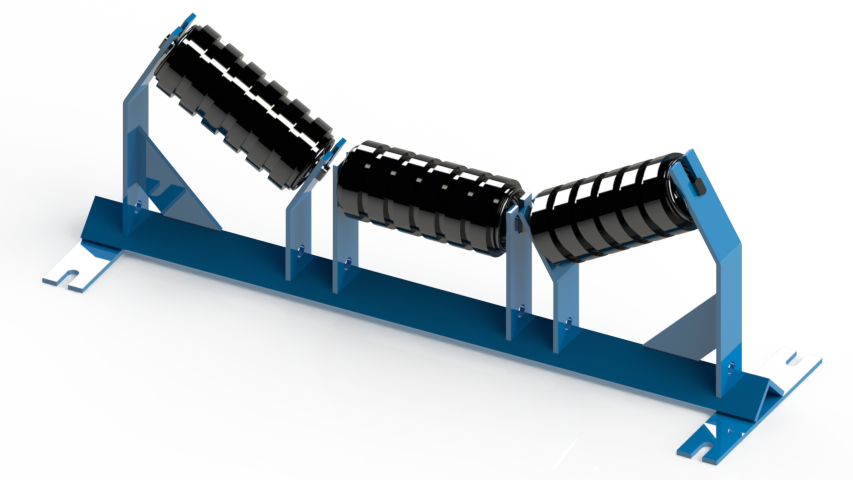

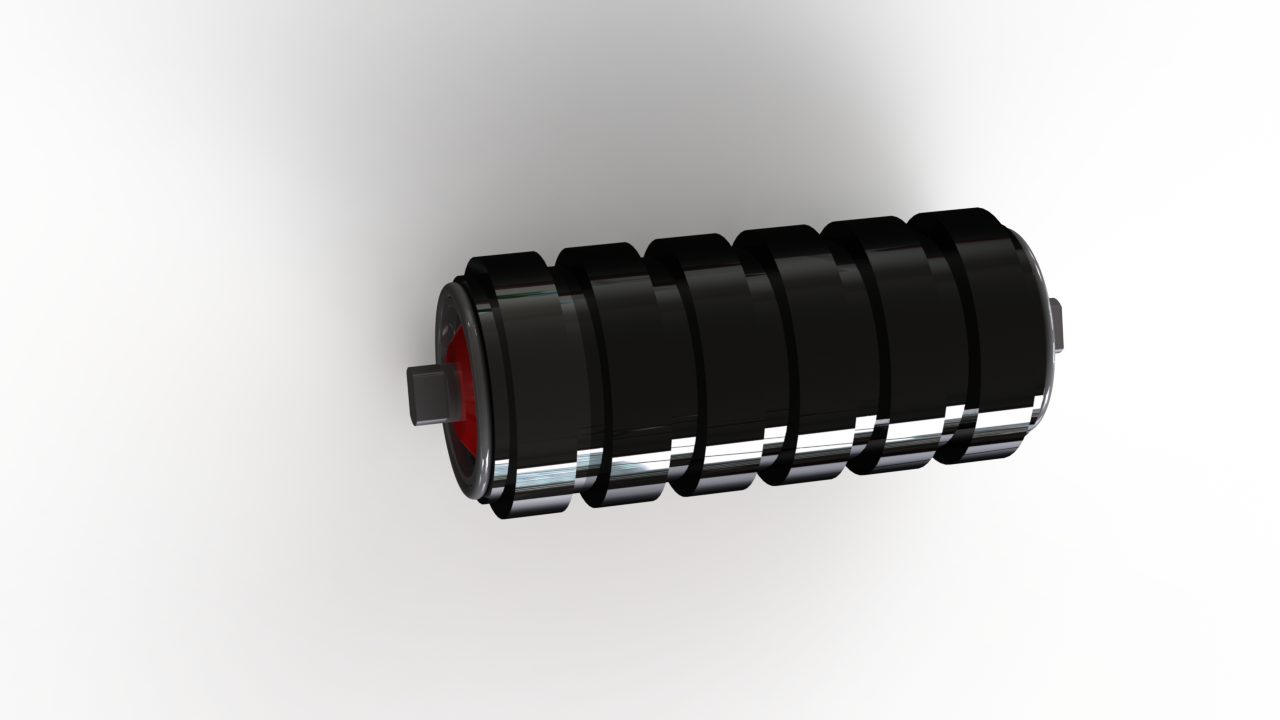

IMPACT IDLERS

RETURN IDLERS

SELF ALIGNING CARRYING IDLERS

SELF ALIGNING RETURN IDLERS

GUIDE ROLLERS

HDPE IDLER ROLLER

UHMWPE IDLER ROLLERS

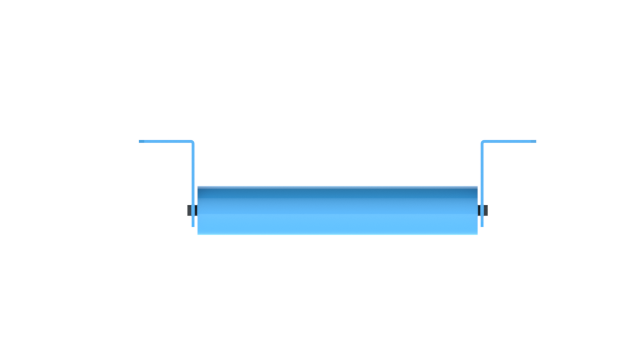

RETURN IDLERS

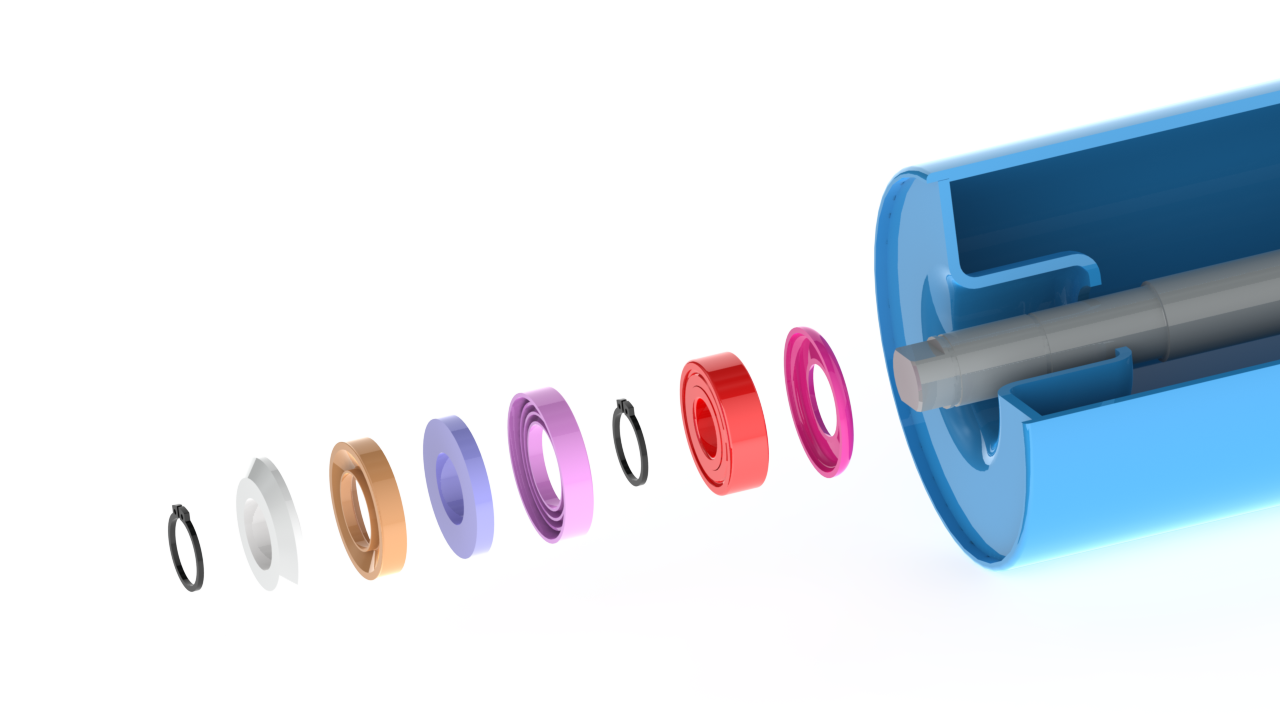

CARRYING IDLER ROLLERS

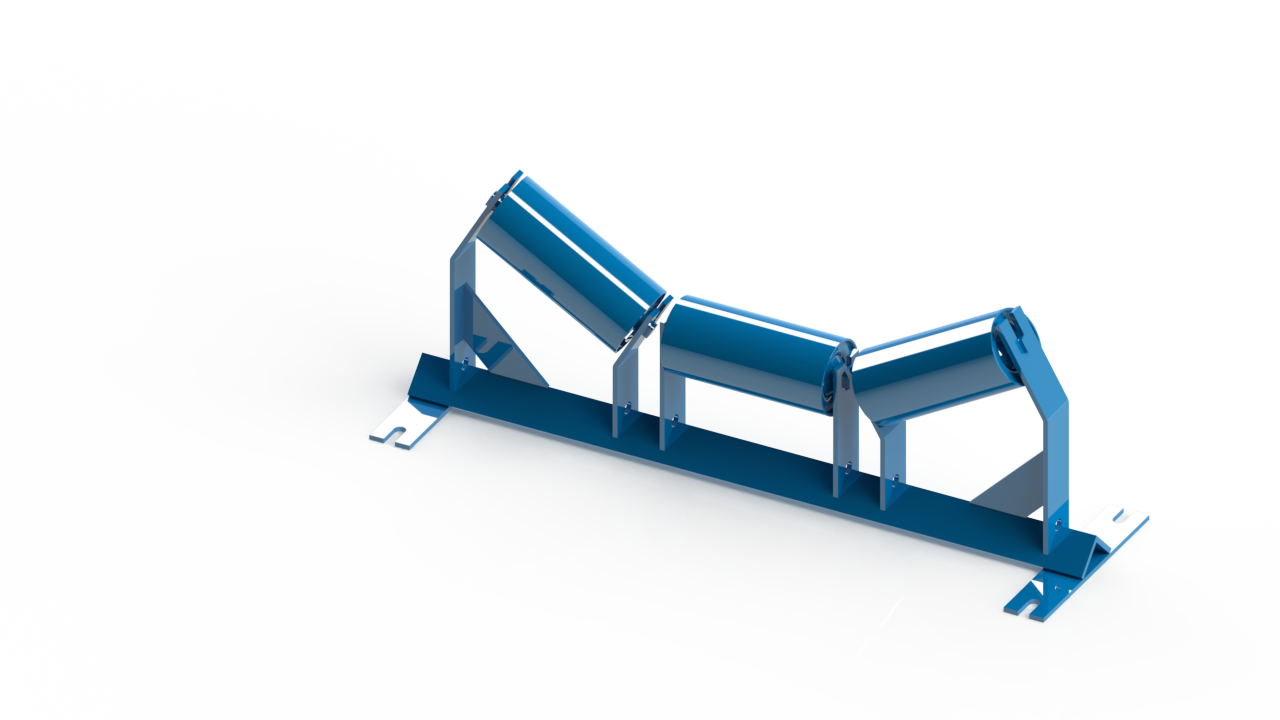

Troughing carrying idlers are used to carry conveyor belt and support bulk materials on conveyor belt working surface.

We manufacture Troughing idler Frames and Roller For:

- Conveyor Belt Width : 400mm to 2200mm

- Roller Shell Diameter : 60mm to 168mm

- Shaft Bearing Diameter : 20mm to 45mm

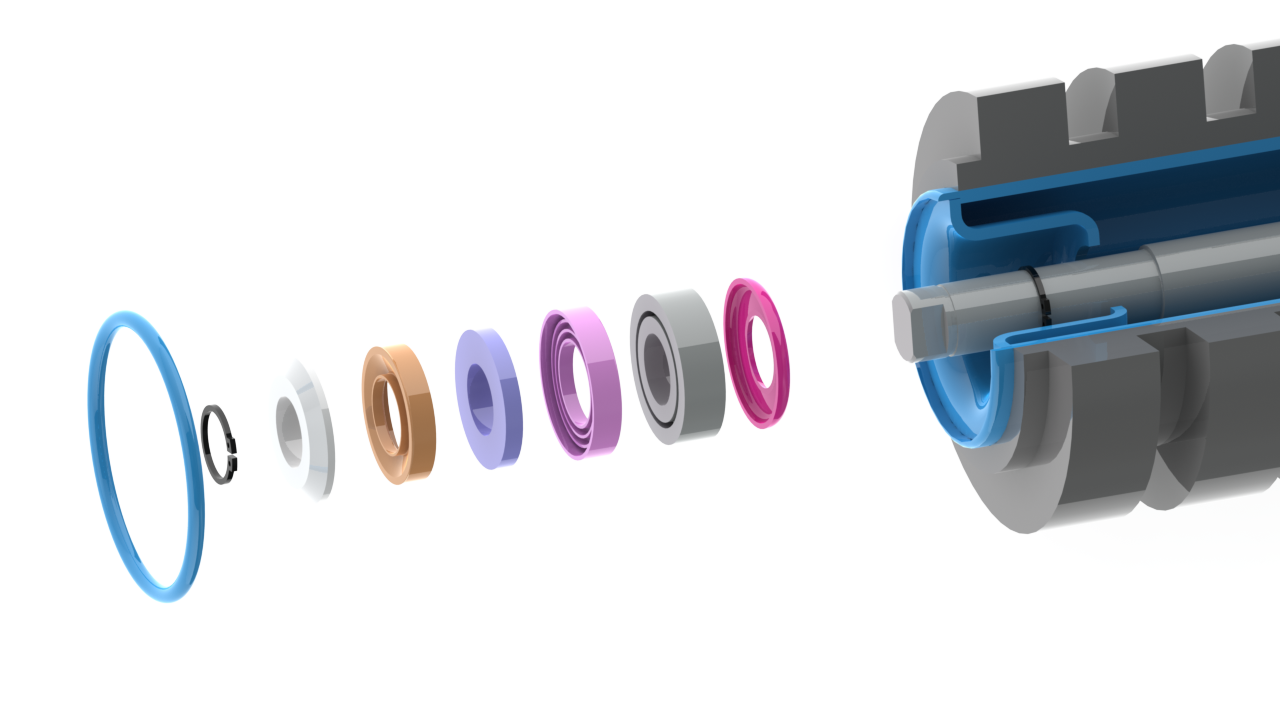

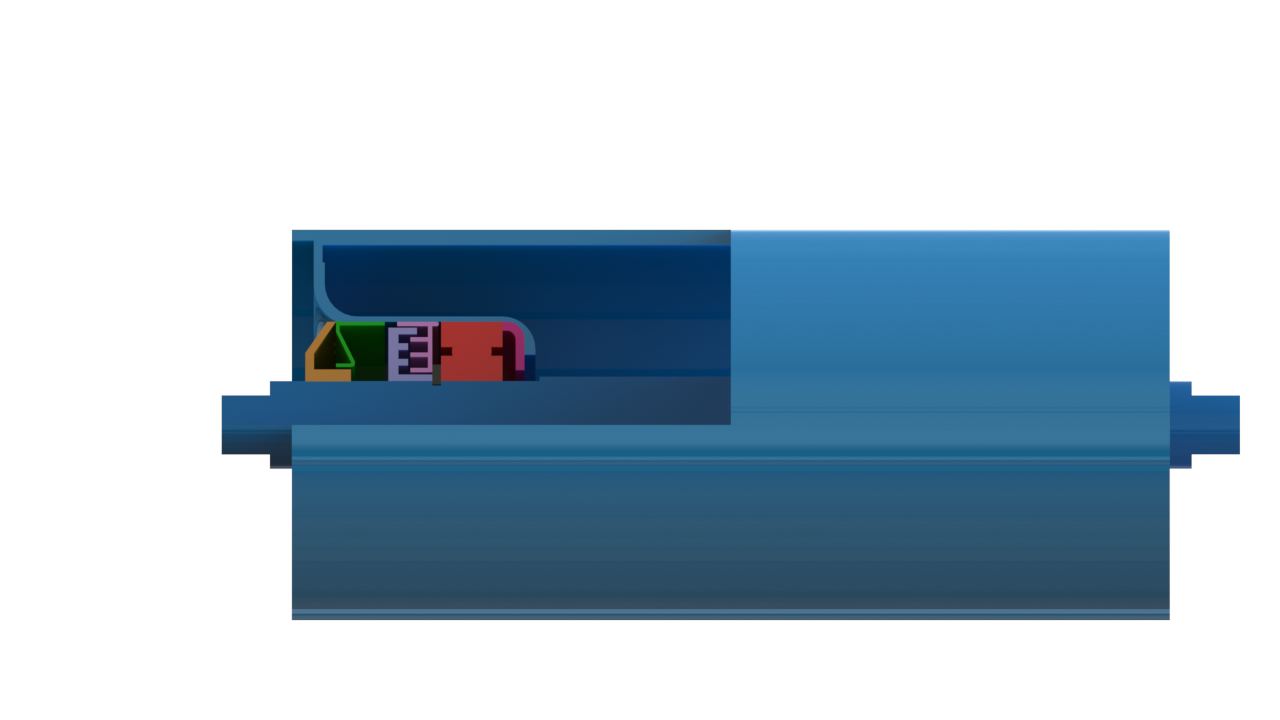

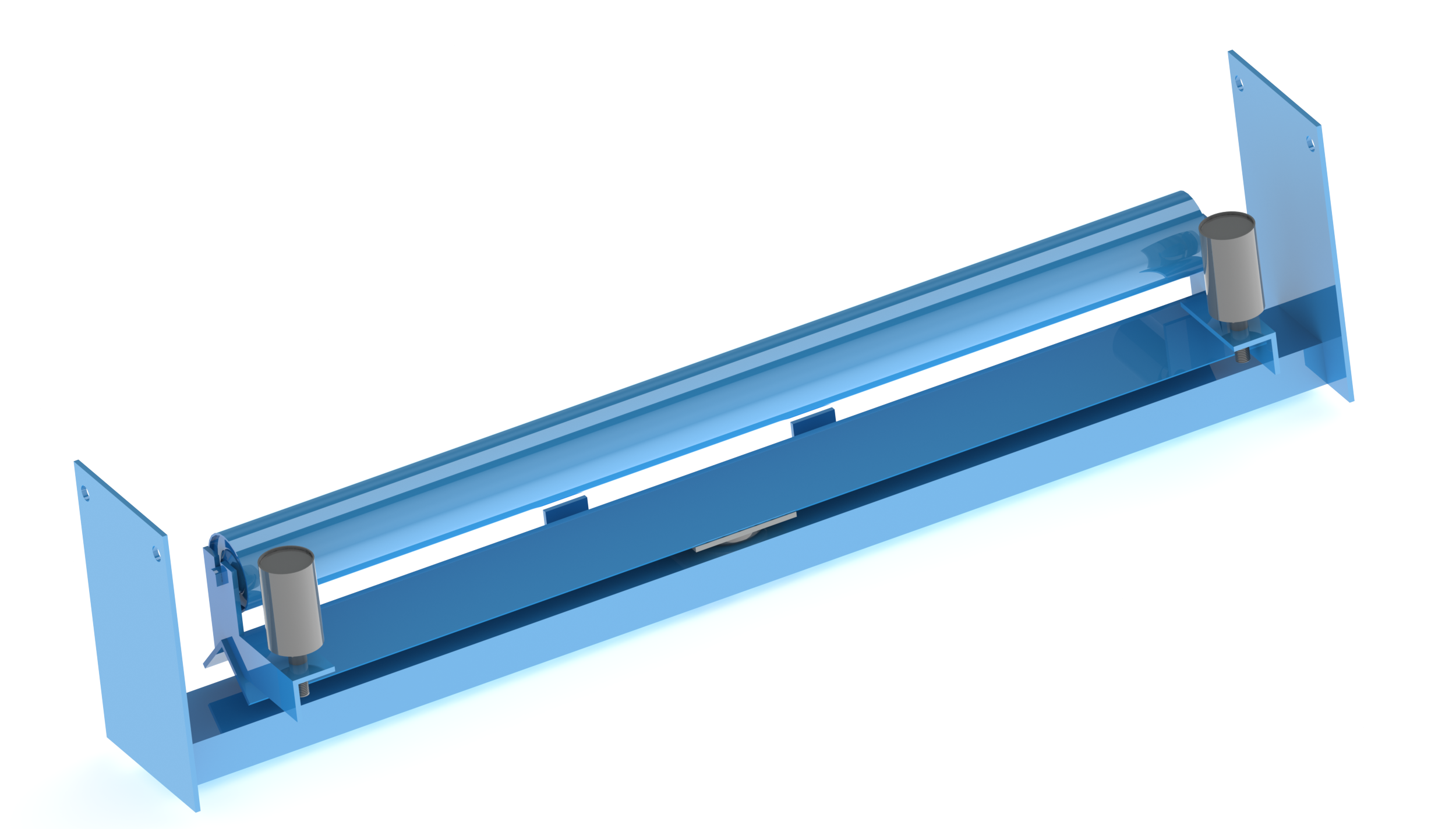

IMPACT IDLER ROLLERS

Impact rollers are installed below the drop material section of a conveyor to reduce the impact of the falling material on the conveyor or belt to extend the service life of the conveyor belt.

Impact Idlers manufactured by OEWIPL are made of rubber rings (89mm to 200mm) fixed on to steel shells of idlers.

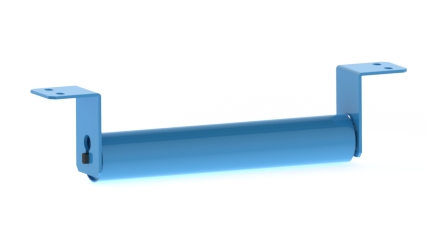

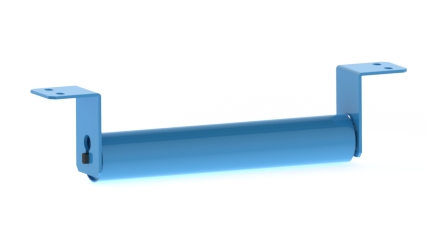

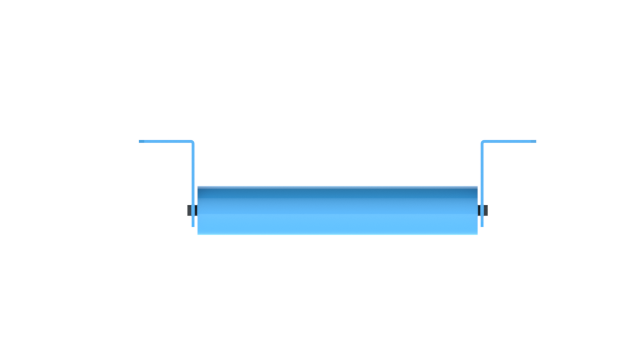

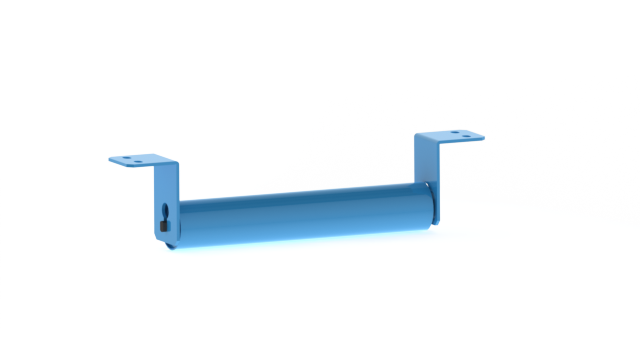

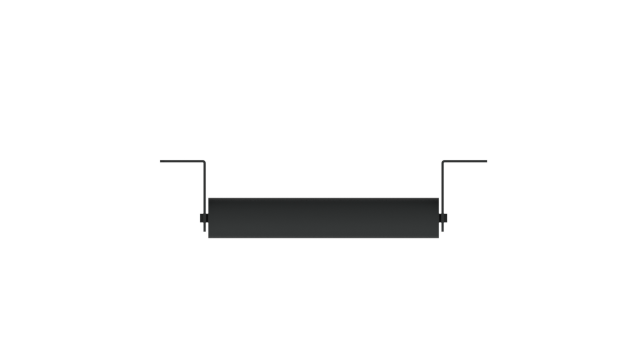

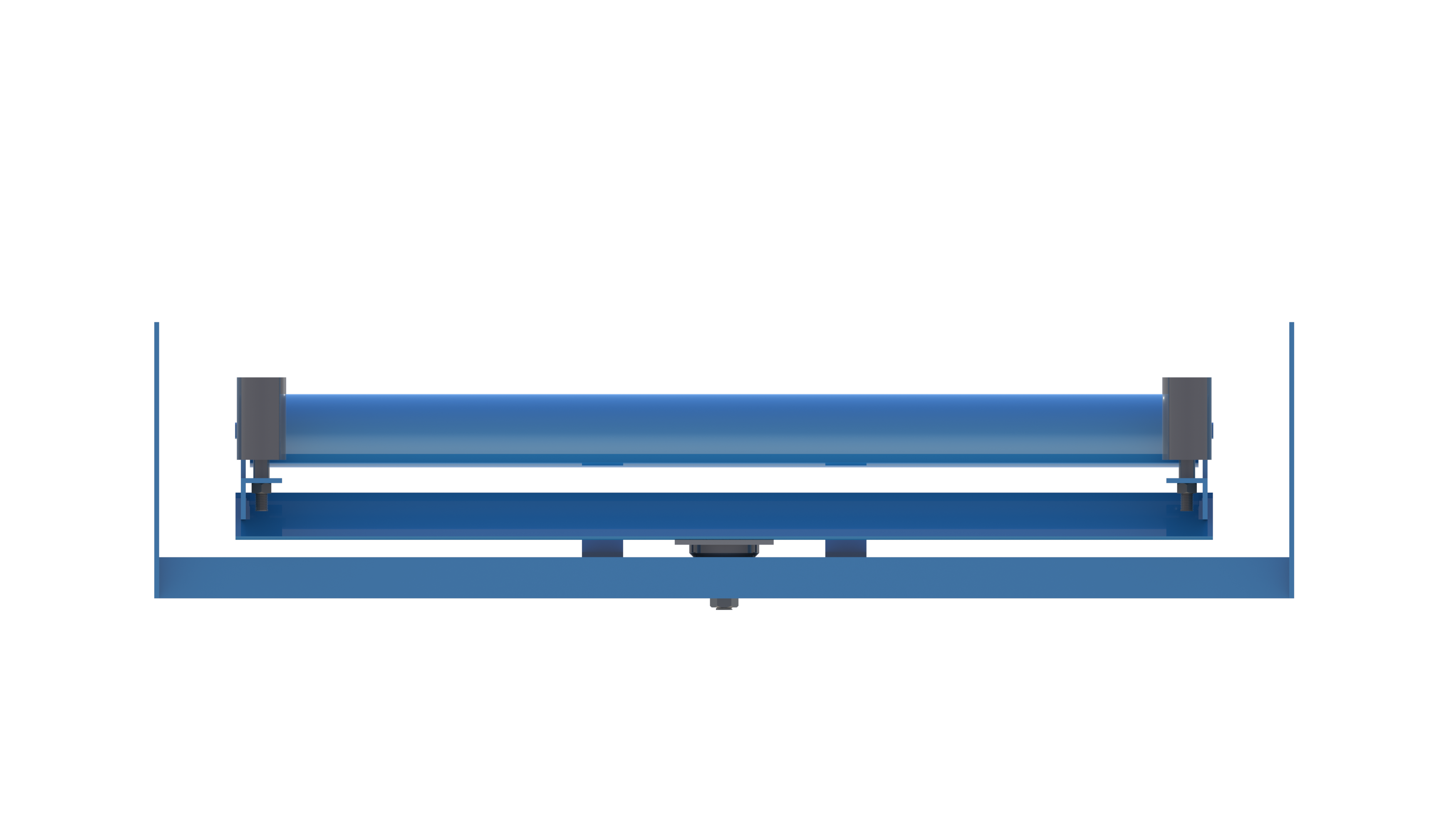

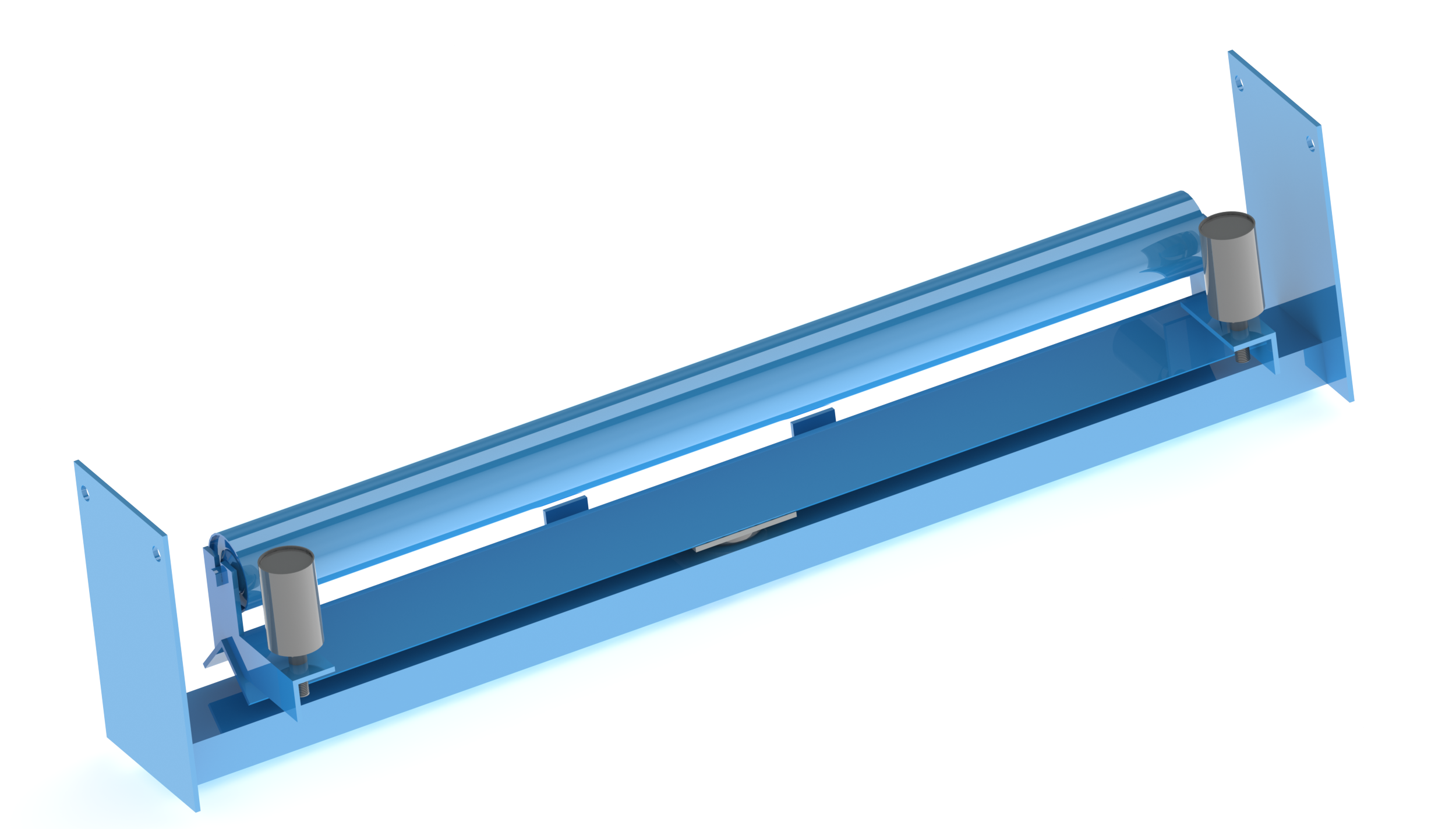

RETURN IDLER

Belt conveyors return idlers are used to support the belt as it cycles around to be loaded again. Various designs of return rollers are being manufactured by us regularly :

- Self Cleaning Return Idler

- V – Return Idlers

- Garland Return Idlers

- Live – Shaft Return Idlers

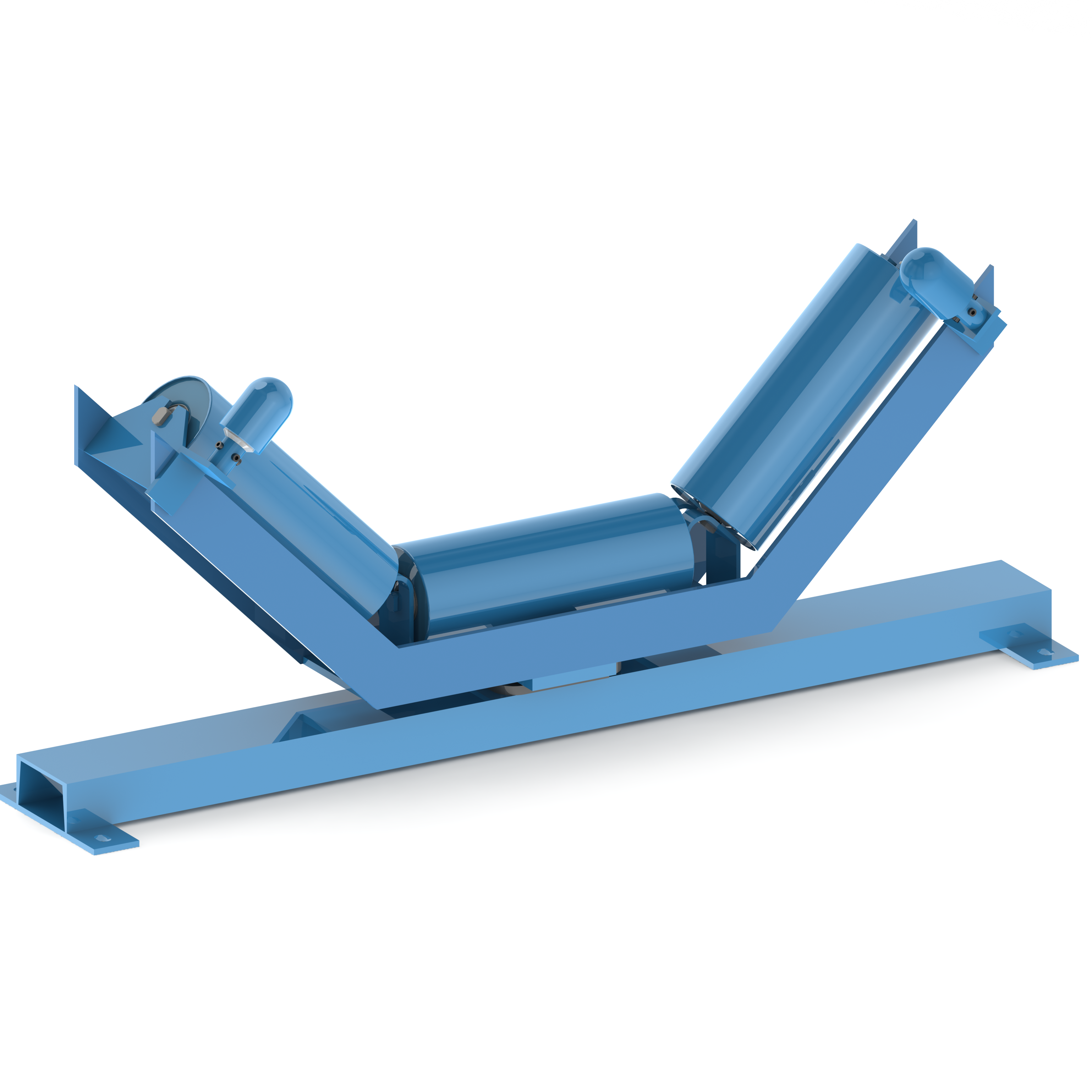

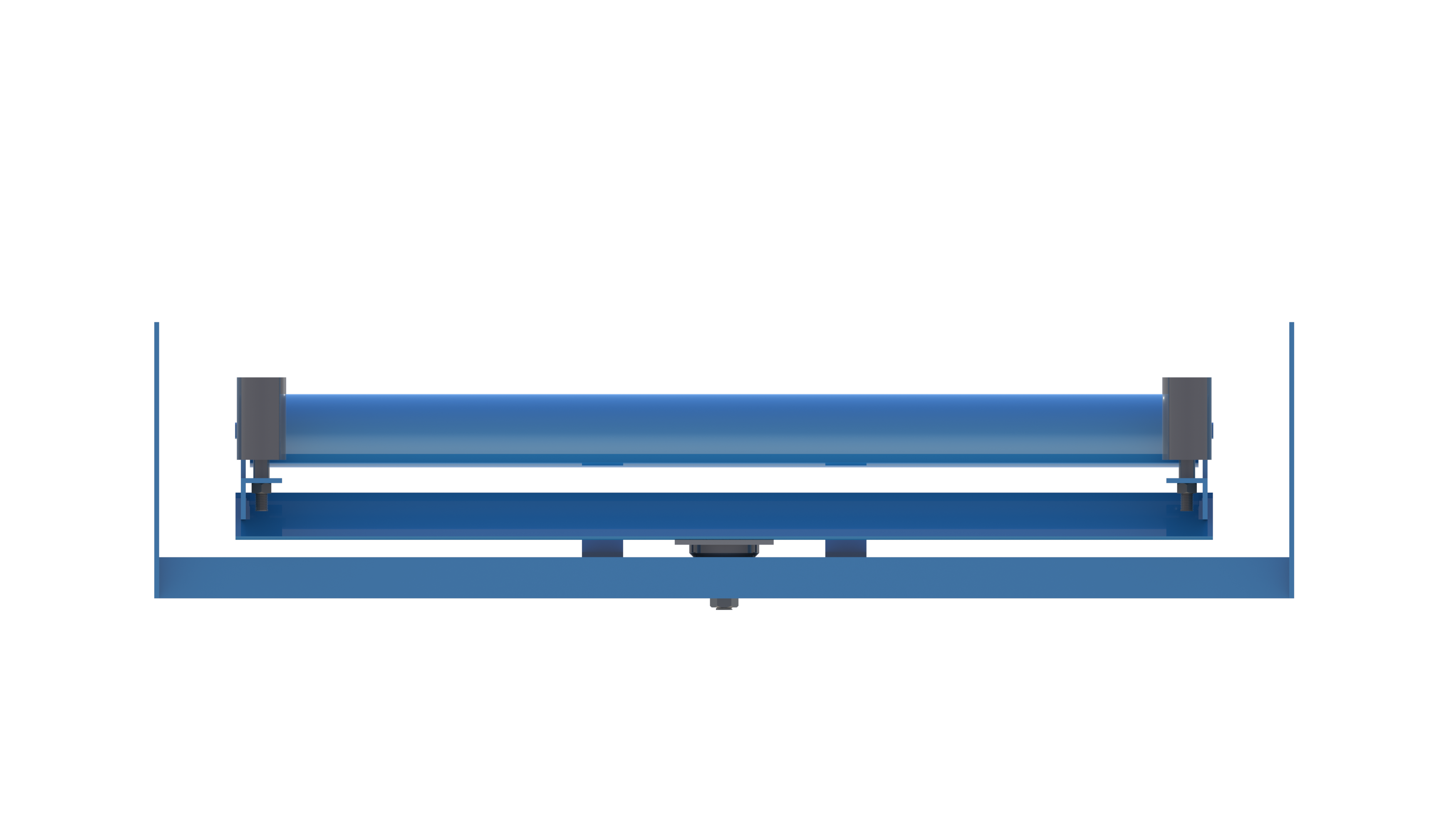

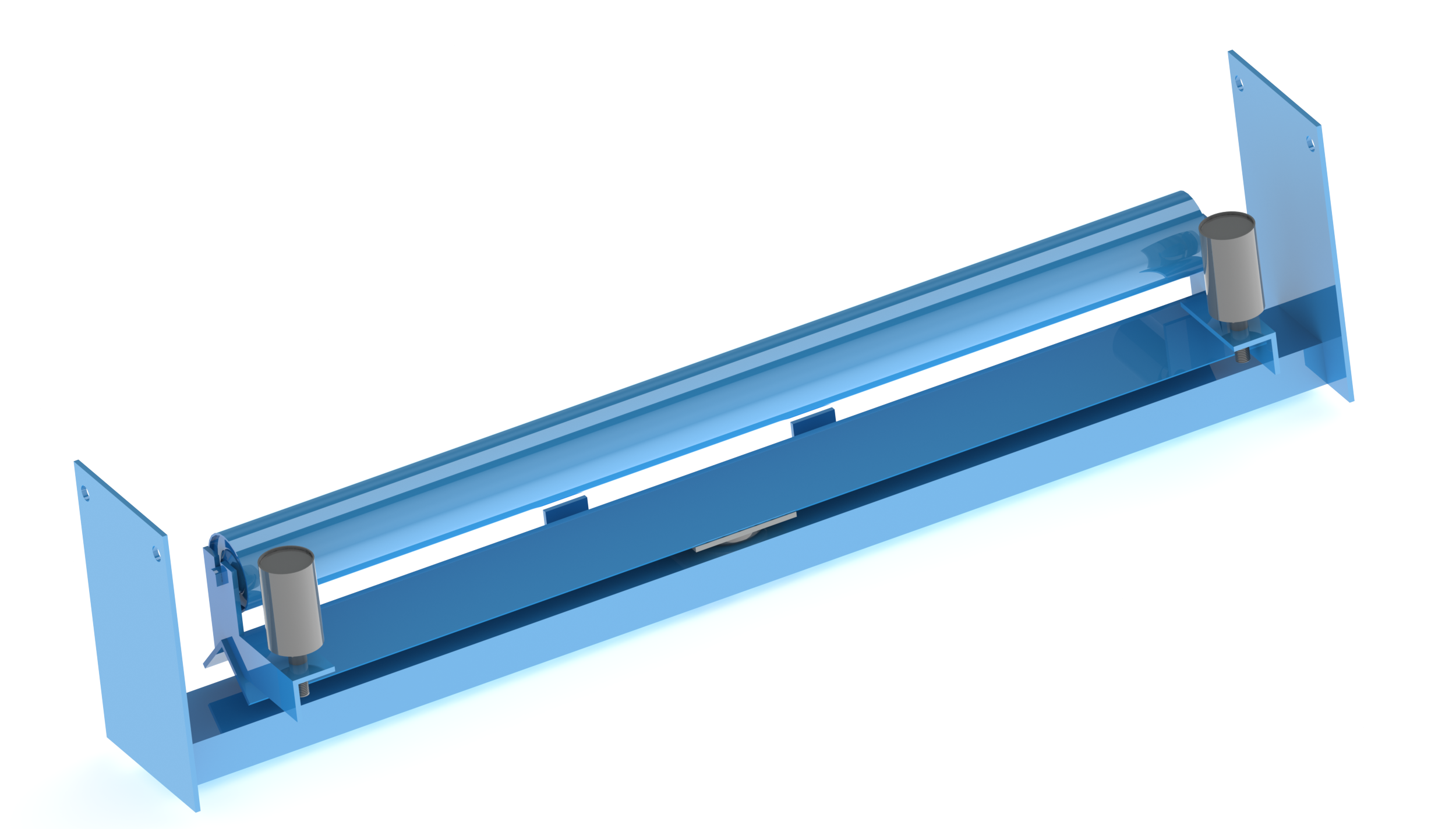

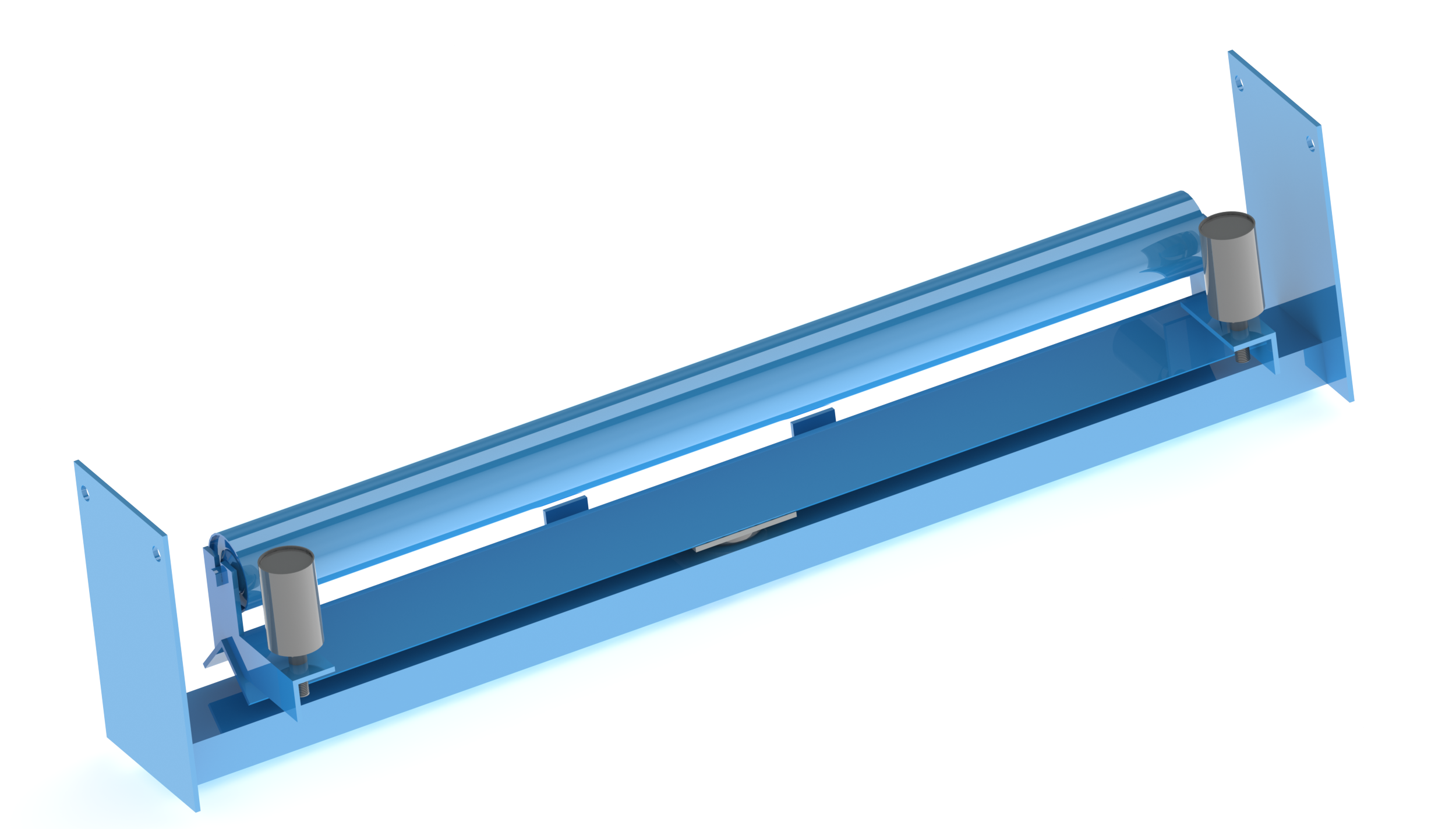

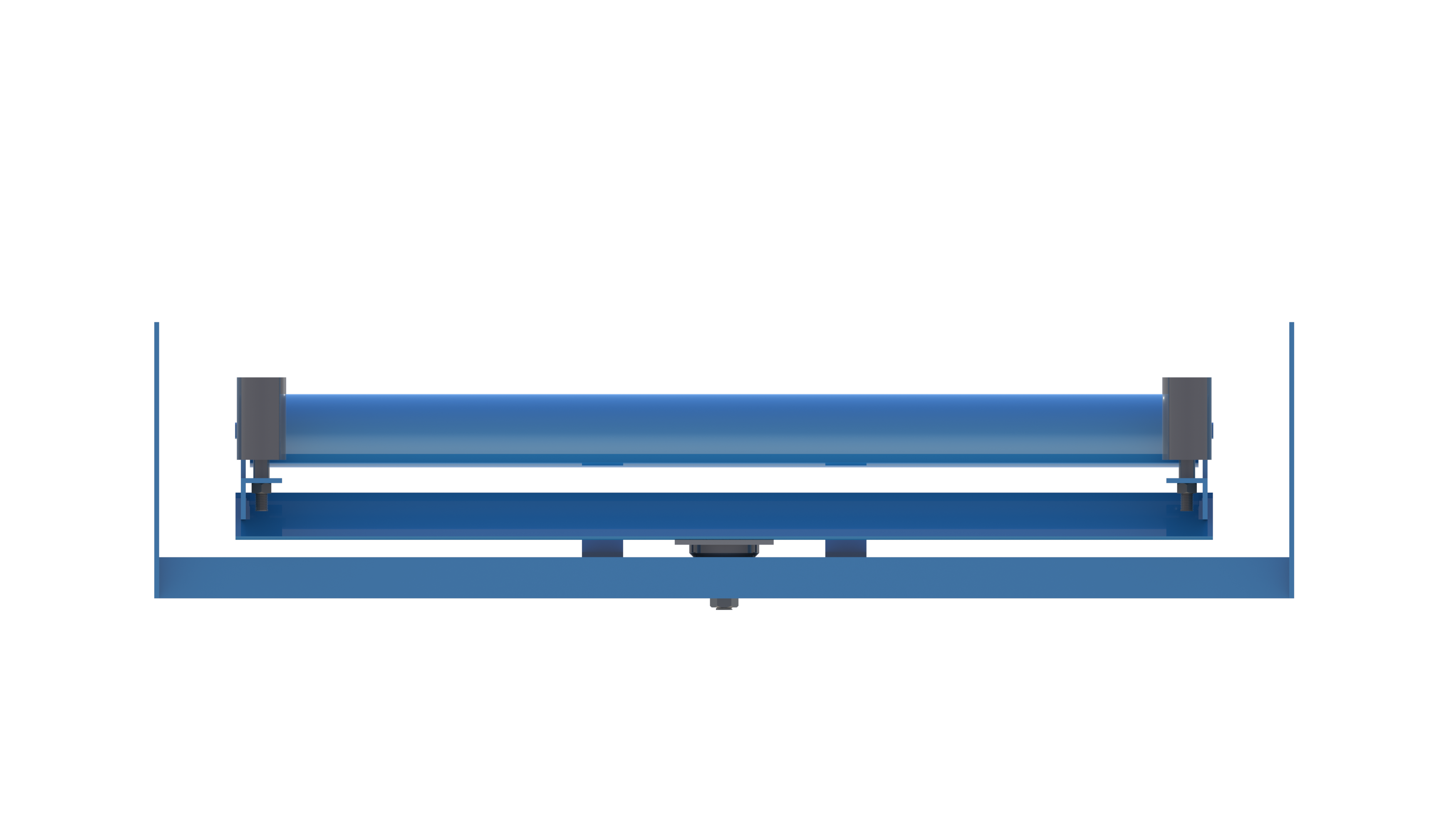

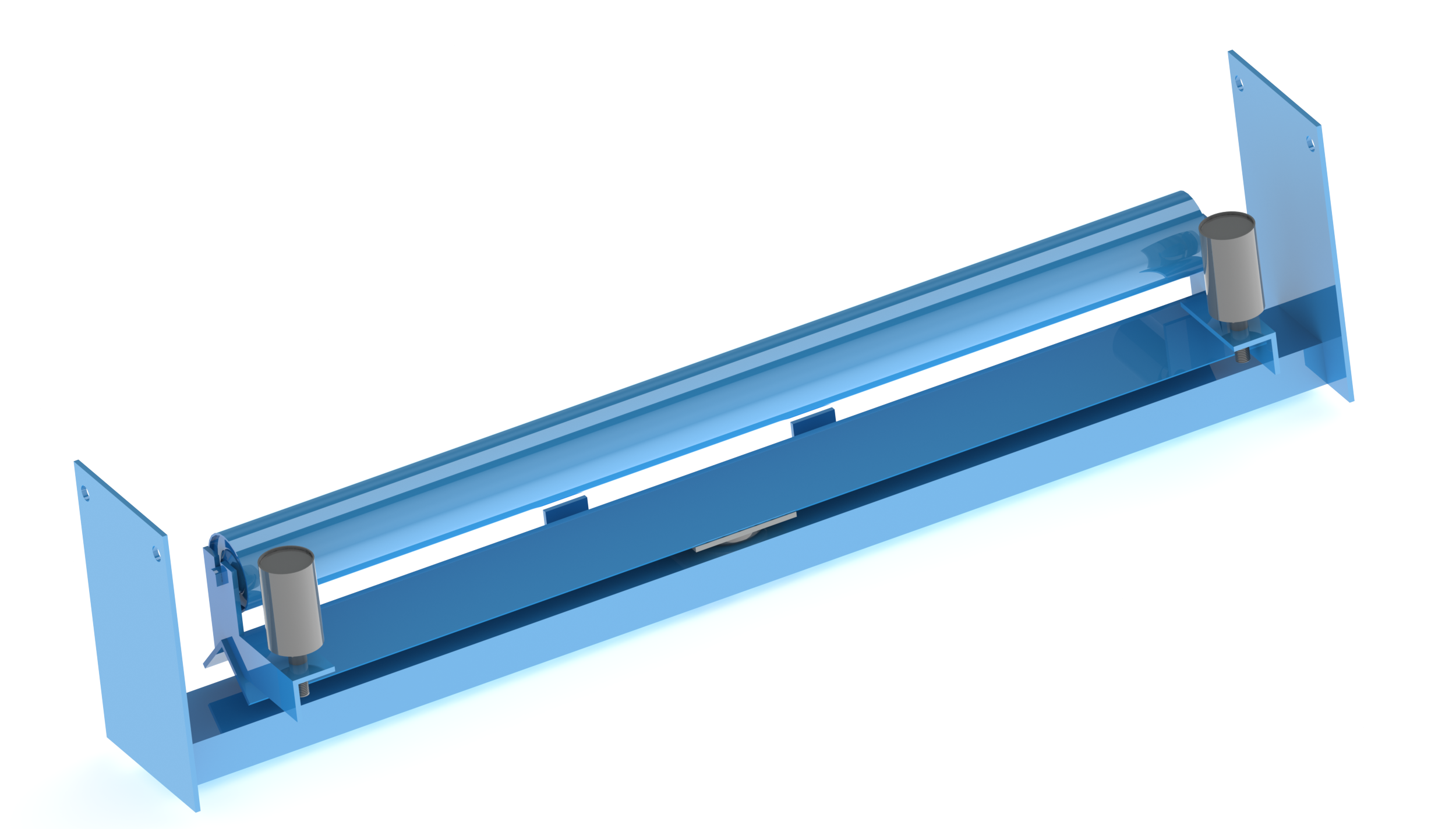

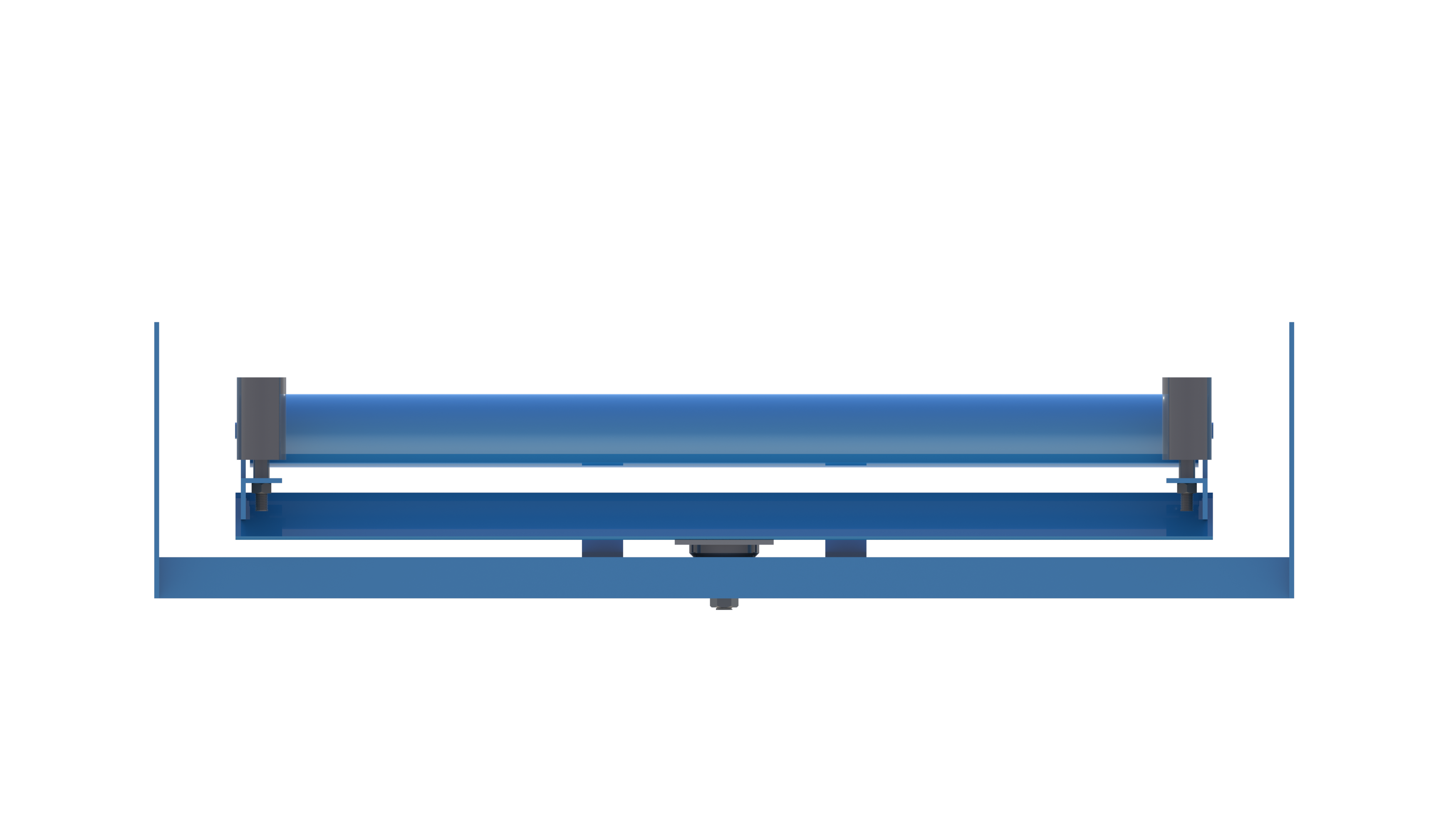

SELF ALIGNING CARRYING IDLERS

Self-aligning idlers are conveyor belt components designed to correct belt misalignment automatically . They ensure smooth operation by adjusting their angle to center the belt ,reducing wear and improving efficiency.

We manufacture Self-Aligning Idlers for both Carrying side and Return side of the conveyor for conveyor up to 2200mm Belt Widths.

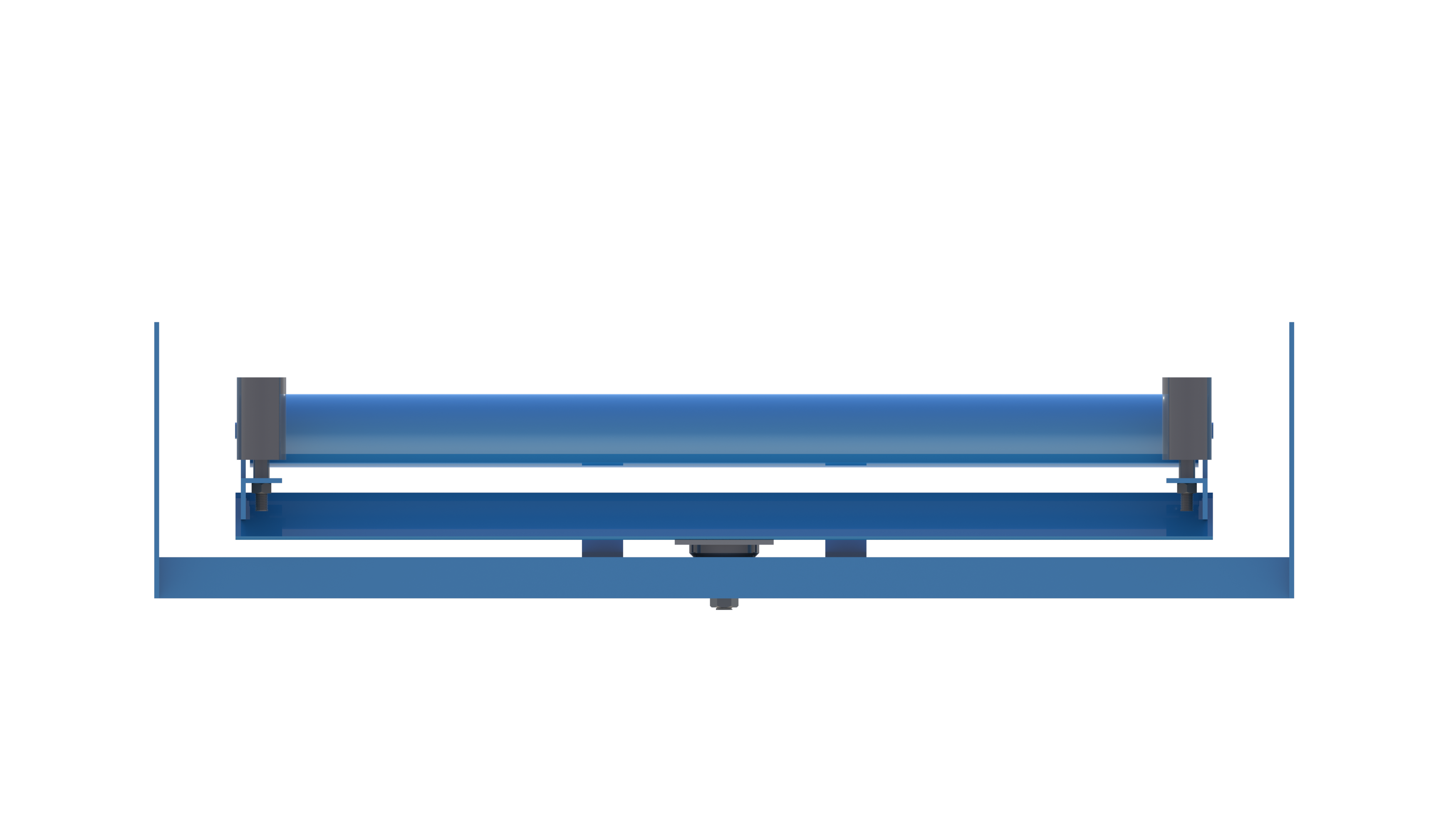

SELF ALIGNING RETURN IDLERS

Self-aligning return idlers are essential components in conveyor systems, designed to ensure proper belt alignment and minimize belt tracking issues. They automatically adjust to correct any belt misalignment, reducing wear and tear on the belt and improving operational efficiency. These idlers are robust, durable, and suitable for heavy-duty applications, ensuring smooth conveyor operation even under challenging conditions. Available in various sizes, they are easy to install and maintain, making them a reliable choice for industries like mining, cement, and stone crushing.

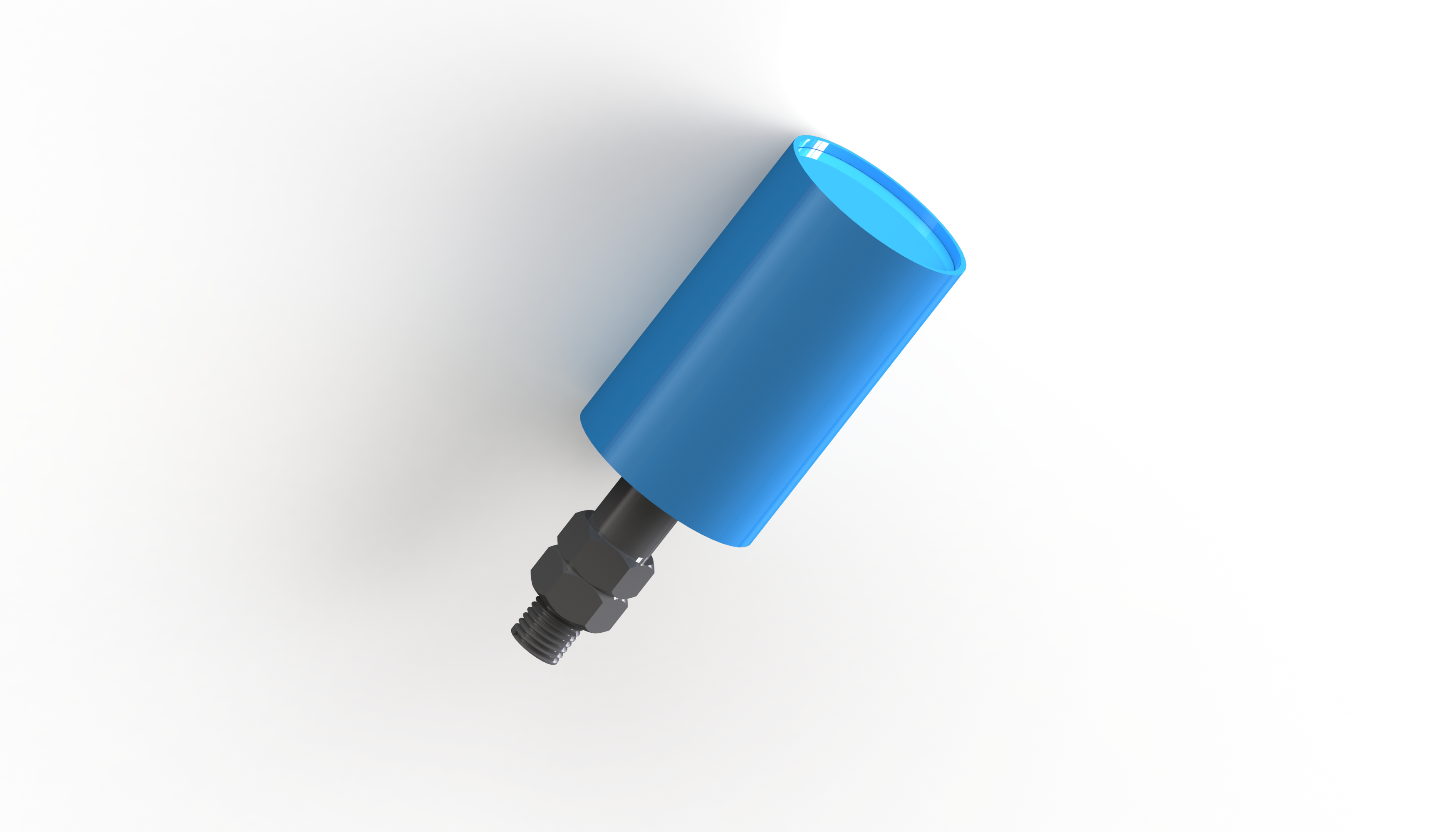

GUIDE ROLLERS

Guide rollers are essential components used in conveyor systems to ensure the smooth and accurate movement of belts or materials. They are designed to guide and support the belt, preventing misalignment and reducing wear and tear. Made from durable materials like steel or polyurethane, guide rollers are built to withstand heavy loads and harsh environments. They are commonly used in industries like mining, manufacturing, and material handling. Guide rollers come in various sizes and designs to suit specific applications, offering high efficiency and long service life. Their low maintenance requirements make them a reliable choice for industrial operations.

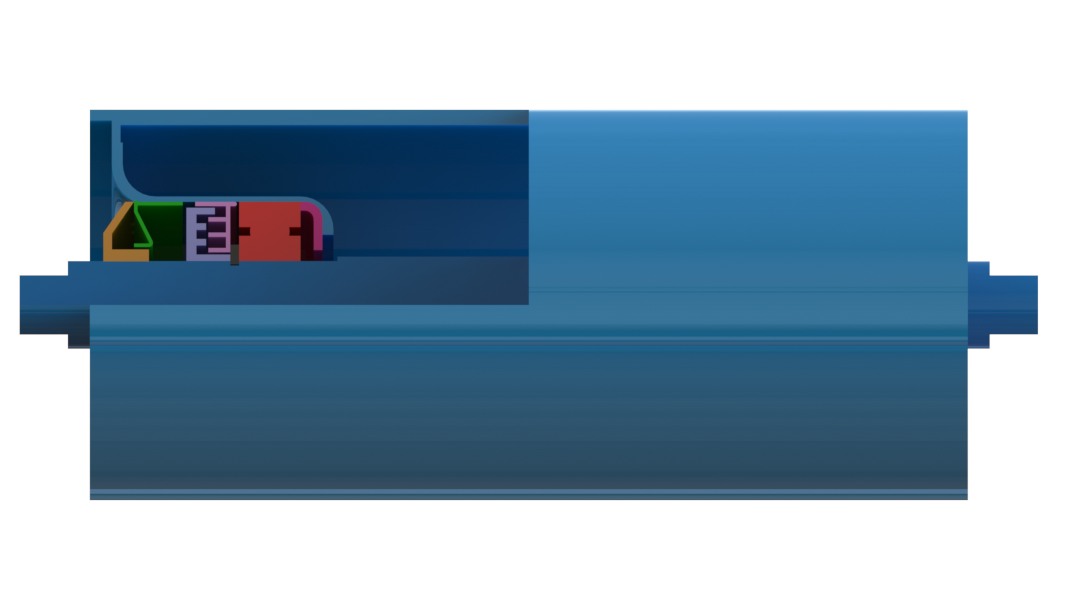

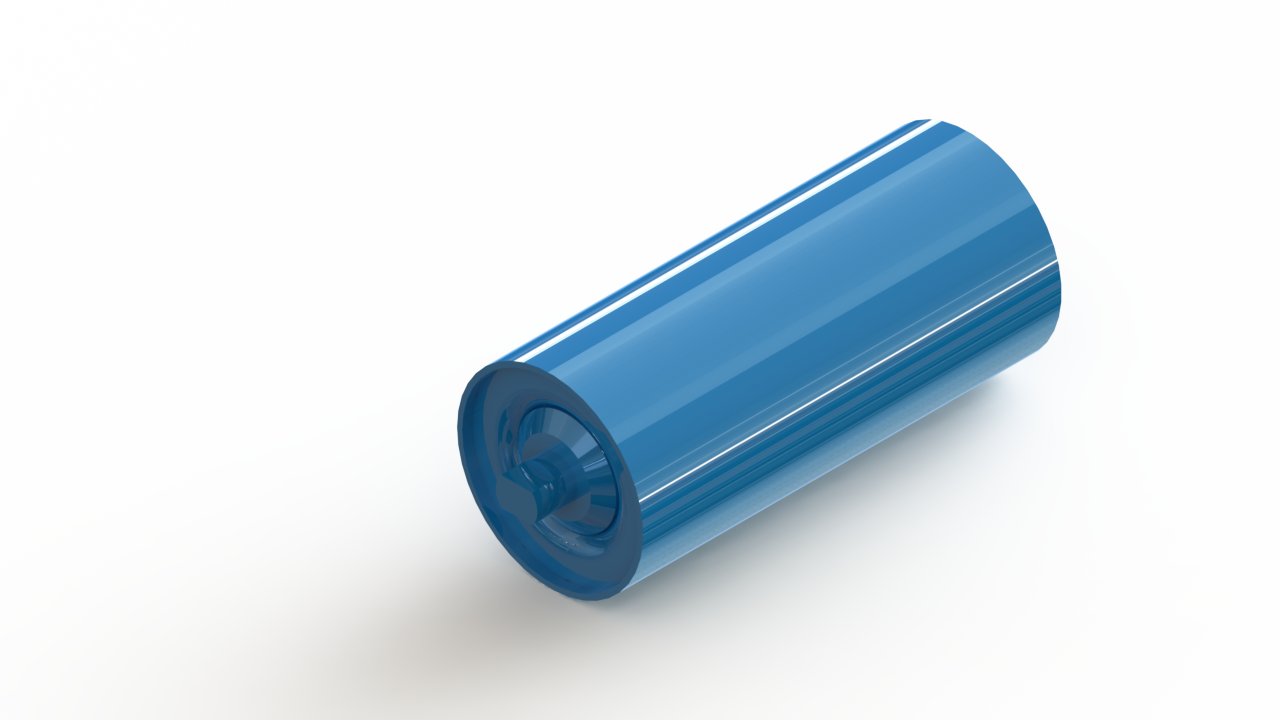

HDPE IDLER ROLLER

HDPE (High-Density Polyethylene) Idler Rollers are designed for durability and efficiency in material handling systems. These rollers are lightweight, corrosion-resistant, and offer low noise operation. Ideal for harsh environments, they minimize belt wear and require minimal maintenance. Available in various sizes and specifications, HDPE idler rollers are perfect for conveyor systems in industries like mining, construction, and agriculture.

UHMWPE IDLER ROLLERS

Ultra-High Molecular Weight Polyethylene (UHMWPE) idler rollers are designed for durability and efficiency in material handling systems. These rollers are lightweight, corrosion-resistant, and have a low coefficient of friction, ensuring smooth operation and minimal wear on conveyor belts. They are ideal for harsh environments, resisting impact, abrasion, and chemical exposure. UHMWPE rollers reduce energy consumption due to their low rolling resistance and are easy to install and maintain. Suitable for industries like mining, cement, and bulk material handling, these rollers enhance conveyor performance and longevity

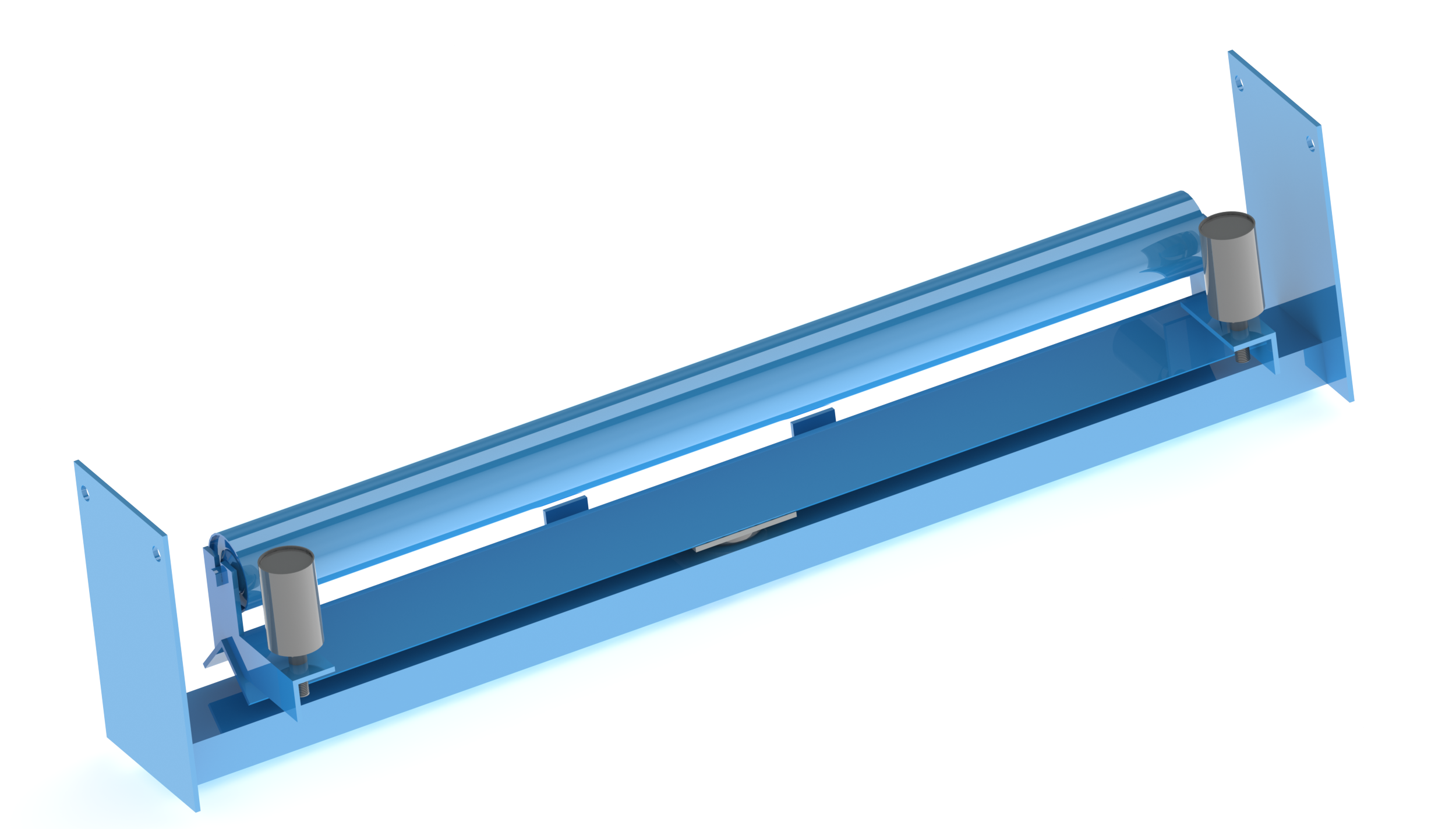

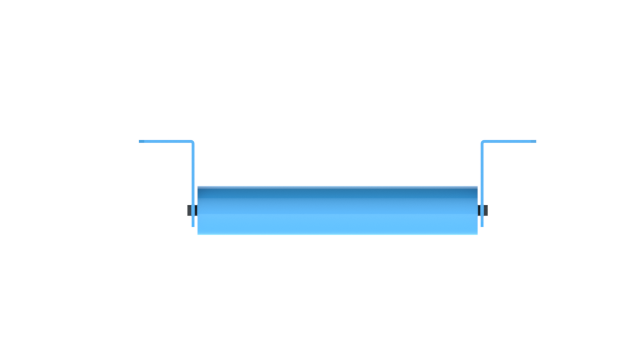

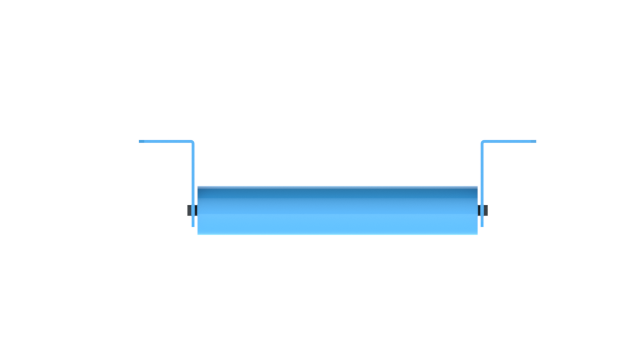

RETURN IDLERS

Return idlers are an essential component of a conveyor belt system, designed to support the return side of the belt as it moves back to the loading point. They help maintain the belt’s alignment and prevent sagging, ensuring smooth and efficient operation. Typically made of durable materials like steel or rubber, return idlers are mounted beneath the conveyor and are spaced at regular intervals. These idlers can be flat or V-shaped, depending on the conveyor’s design and application. Proper maintenance of return idlers is crucial to reduce wear and tear on the belt and to ensure the system’s longevity

using WordPress and

using WordPress and